-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

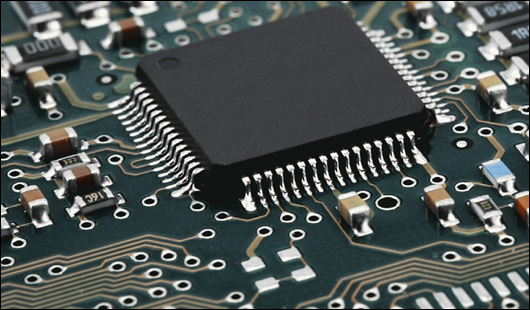

BGA refers to a ball grid array, which is an advanced packaging technology in SMT assembly. BGA is the result of the development of electronic technology and indicates the significant progress of package technology. There are many ball-shape bumps on the surface of the tube, which provides a lot of interconnection points to achieve high-density package purposes. BGA package offers short lead length and ample lead space, making it an ideal solution for high-speed PCB products with high-density circuits.

The benefits and applications of BGA assembly

Why do we treat the BGA package as an advanced assembly technology? Because BGA assembly shows many advantages in high-density PCB products. Firstly, BGA assembly allows small packages for ICs with hundreds of pins, which can integrate more functions while achieving less space utilization. Secondly, BGA packages have excellent electrical performance and heat conduction. Thirdly, its better solderability leads to good manufacturing yield. Due to these advantages, BGA assembly has been widely used in the LED industry, medical industries, wireless and telecommunications, military, aerospace, and satellite, etc.

The BGA assembly capability of APOLLOPCB

APOLLOPCB owns many professional engineers and high-end machines to provide BGA packages with high-quality and high-precision. Turnkey service for BGA assembly and other assembly ways is also available.

· Our advanced equipment in SMT assembly

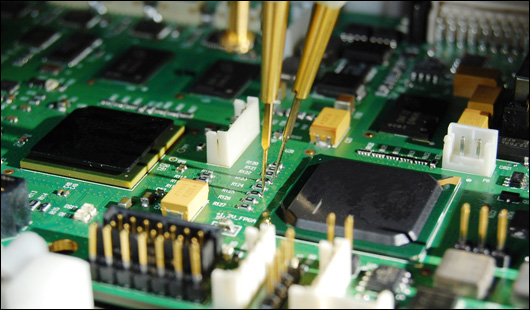

We have a full automated SMT production line to ensure high accuracy and high yield of the assembly. Our latest equipment includes automated solder dispensing machines, automatic placement machines, reflow oven, X-ray and AOI inspection systems, and so on.

· Our BGA inspection process

BGA packages are complicated to inspect the solder quality because the solder ball is under the chip. Traditional optical methods cannot judge if there are detects or cavities in the soldering joints. If there are BGA components in SMT assembly, we usually use a combination inspection method of electrical testing, boundary scan, and automated X-ray inspection to improve detection accuracy.

· Our BGA assembly capabilities

BGA soldering traditionally is done through an automatic process because it needs precise control. APOLLOPCB can build high-quality and reasonable yield rate BGA assembly PCBs for you. The minimum pitch size of BGA we can assemble is 0.25mm. We have these types of BGA assembly service:

Plastic BGA (PBGA)

Ceramic BGA (CBGA)

Micro BGA

Micro Fine Line BGA (MBGA)

Stack BGAs

Lead BGA and leadless BGA

Now, BGA assembly technology has been skillfully mastered by most manufacturers. As a PCB manufacturer with years’ experience, APOLLOPCB provides BGA assemblies above industry standard with strict factory inspection. It is advisable to do BGA assembly for your PCBs from experts, APOLLOPCB must be your best choice.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB