-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

The electrical test is performed before delivering the PCBs. Usually, all the PCBs will go through E-test after manufacturing. Open circuits and short circuits are the default test types.APOLLOPCBalso provides other test types according to customers’ requirements.

The function of the electrical test for PCBs

The electrical tests have become an irreplaceable test method for PCBs with blind vias and buried vias except for the visual inspection and the AOI. Only E-test can check out the missing connections on the board. The main electrical testing procedures for PCBs are listed as following:

· Circuits open and short testing

· Capacitance testing

· Resistance testing

· Comparative testing

· Flip testing

· Continuity testing

· Adjacency testing

Two major types of test equipment used in electrical test

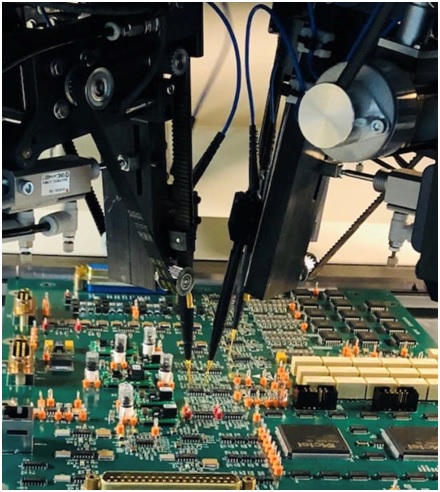

· Flying probe

A flying probe is the machine used for the flying probe testing method. With software that suitable for the PCB layout, the flying probes check the signal one by one. The whole testing time is about 1 to 3 minutes.

Advantages:

No need for fixed testing tools

Low cost

Short delivery time (suitable for PCB prototyping)

· Bed of nails fixture

Bed of nail is a specific tool for fixture test. Each type of PCB has a bed of nail. This testing method always needs 5 to 10 seconds for one PCB. Because it is necessary to make a test fixture for each type of PCB, which is not economical for PCB prototypes.

Advantages:

Fast speed

More accurate

The fix tools are reusable. (suitable for batch production)

These two types of E-test both have advantages and disadvantages. The flying probe test may be cheaper at initial cost, but the bed of nails fixture test is a higher cost-effective for batch orders.

Electrical test at APOLLOPCB

With the PCB designs become more complex and smaller, the need for E-test becomes more critical. All the PCBs need to be tested by one of the E-test methods to ensure that all vias are connected because AOI cannot find this issue.

As a professional PCB manufacturer,APOLLOPCBprovides PCBs that have been tested with high-level testing equipment by skilled quality assurance professionals. To get more information about the quality tests or ordering PCBs for your business, contact us now!

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB