-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

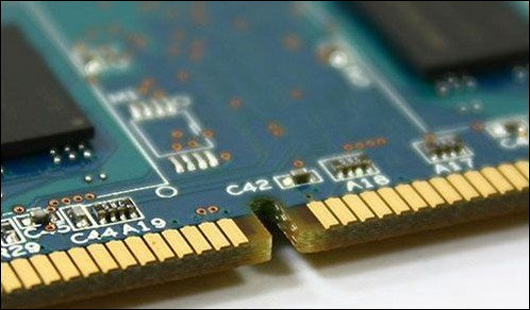

What are the gold fingers?

Gold fingers are the gold-plated narrow connectors on the edge of printed circuit boards (PCBs), building connections between multiple boards or between the secondary PCBs and the motherboard of a computer. The reason for using gold to make the fingers is that gold has high electrical conductivity and corrosion resistance. The raw material usually is flash gold, and sometimes gold is combined with Nickel and Cobalt to increase the abrasive resistance because gold fingers need to be plugged in and out frequently.

There are two kinds of gold that apply to the plating process of the gold fingers. One is electroless nickel immersion gold (ENIG). ENIG is cost-effective and easier to solder, but it is soft and thin. Another is electroplated hard gold. This gold is solid and thicker, which is more wear-resistant. The plating process of the gold fingers involves many meticulous steps, which makes sure that each PCBs from the production line is properly configured to transmit the right signals.

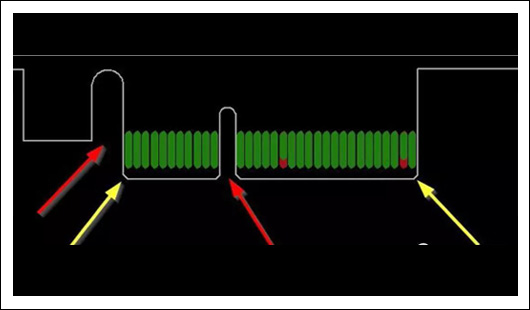

Some design specifications for PCB gold fingers

The design of gold fingers should follow some rules so that they can normally work during the plating process. If you don’t obey these rules, the PCBs may not be able to connect with the motherboard successfully, or the PCB may not be suitable for the slots on the motherboard.

l Gold fingers should be placed outwards from the PCBs’ center.

l No solder mask or screen printing near the gold fingers

l Keep a distance of at least 1.0mm between gold fingers and the outline of the PCB.

l No plated through holes (PTH) is preferred within 1.0mm of gold fingers.

l The thickness of the board should be 1.0mm or above.

l For the gold fingers that need to beveled 45°, there should be enough space between the finger and the edge of the board to avoid damage. At present, APOLLOPCB can only do 30° beveling for the gold fingers.

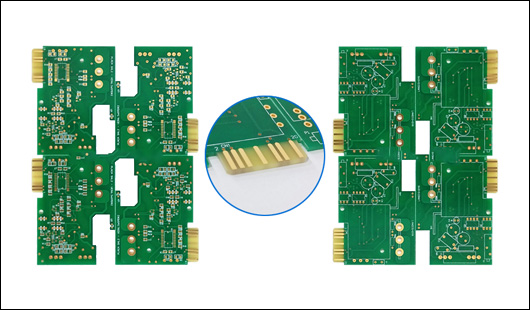

The applications of gold fingers

Gold fingers make communication possible between two or multiple PCBs. As a connecting point, the functions of gold fingers include conduct function and preventing damages during use. So, gold fingers can be applied in many electronics based on the designers’ purpose. Some typical applications are:

l Used for the PCBs of memory card readers.

l The devices that communicate with digital signals (Smartwatches and smartphones).

l Used as a connector to connect the external components to the PCBs.

l Used as a connector to connect the daughterboard to the computers.

l Used as special adapters to add numerous performance to a computer.

l Some external devices, like speakers, scanners, and monitors, can be added to a computer with gold fingers.

l Used as connecting contacts in computerized industrial machinery.

Nowadays, more and more technologies rely on gold fingers. The manufacturing standard of gold fingers becomes higher to ensure the most top performance of high-tech products. APOLLOPCB is one of the most professional and experienced PCB manufacturers in China, which can provide turnkey service of PCB assembly prototype and small volume PCB fabrication. Please contact us if you need more details about gold fingers or other processes in PCB manufacturing.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB