-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

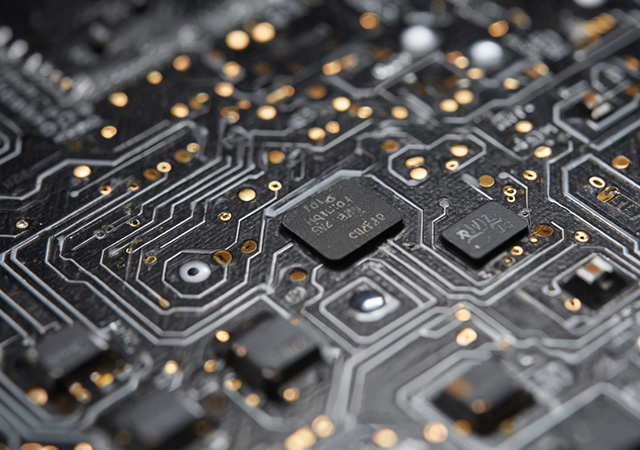

Aluminum printed circuit boards (PCBs) have transcended their role as niche thermal management solutions to become foundational components in diverse electronic systems. By merging the mechanical resilience of aluminum with advanced conductive and insulating materials, these PCBs address the critical challenges of power density, miniaturization, and environmental sustainability. This article explores the latest advancements in aluminum PCB technology, focusing on material innovations, design breakthroughs, and emerging applications that are reshaping industries from consumer electronics to renewable energy.

In the intricate ecosystem of modern electronics, the aluminum PCB stackup serves as a critical architectural framework, balancing thermal efficiency, electrical performance, and mechanical stability. Unlike traditional PCB stackups reliant on non-metallic cores, aluminum-based configurations leverage the unique properties of aluminum to address the demands of high-power, high-density devices. This article explores the foundational structure, design principles, material interactions, manufacturing considerations, and diverse applications of aluminum PCB stackups, providing a comprehensive guide to their role in advancing electronic systems.

In the realm of high-performance electronics, one-size-fits-all solutions often fall short of meeting the unique demands of specialized applications. Custom aluminum PCB stackup design emerges as a critical engineering approach, enabling engineers to tailor layer configurations, material selections, and thermal pathways to address specific challenges—whether it’s extreme temperature resilience, high-frequency signal integrity, or compact form factors. This article explores the principles, methodologies, and benefits of custom aluminum PCB stackup design, highlighting its role in solving complex engineering problems across industries.

In the realm of high-power, high-density electronics, the 4-layer aluminum PCB stackup has emerged as a sophisticated solution, balancing thermal efficiency, signal integrity, and mechanical robustness. Unlike simpler single or double-layer designs, this multi-layer configuration integrates dedicated layers for power distribution, signal routing, and heat dissipation, making it ideal for applications demanding complex functionality in compact form factors. This article explores the structural composition, material selection, design methodologies, manufacturing processes, and key applications of 4-layer aluminum PCB stackups, highlighting their role in enabling next-generation electronic systems.

In the dynamic world of electronics, where miniaturization, power density, and reliability are paramount, aluminum printed circuit boards (PCBs) have emerged as a transformative technology. Unlike traditional PCBs that rely on non-metallic cores, aluminum PCBs leverage the unique properties of aluminum to address critical challenges in thermal management, mechanical stability, and design flexibility. This article explores the core attributes, material innovations, design methodologies, manufacturing breakthroughs, diverse applications, and future directions of aluminum PCBs, highlighting their role in enabling next-generation electronic devices across industries.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB