-

- PCB TYPE

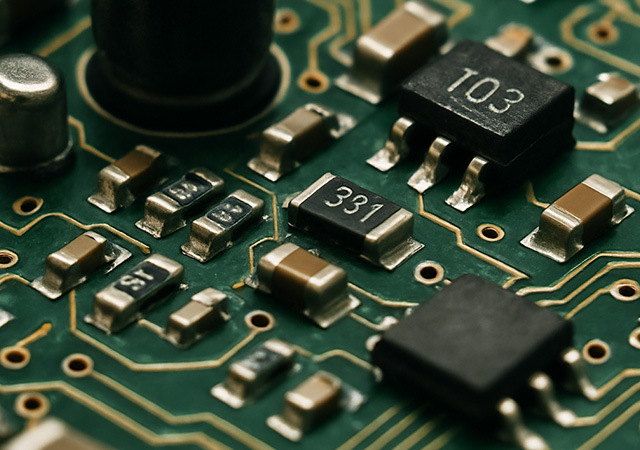

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

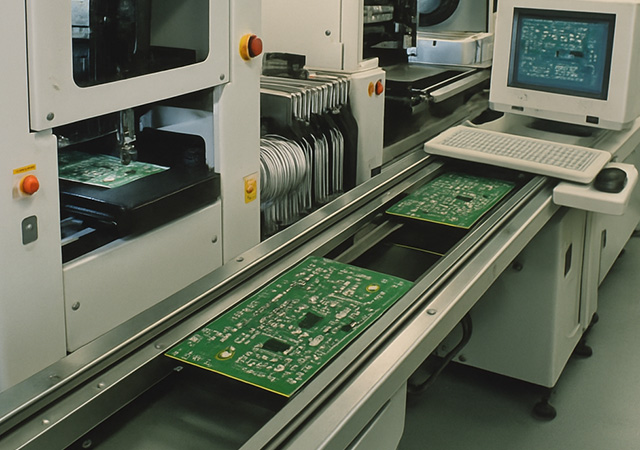

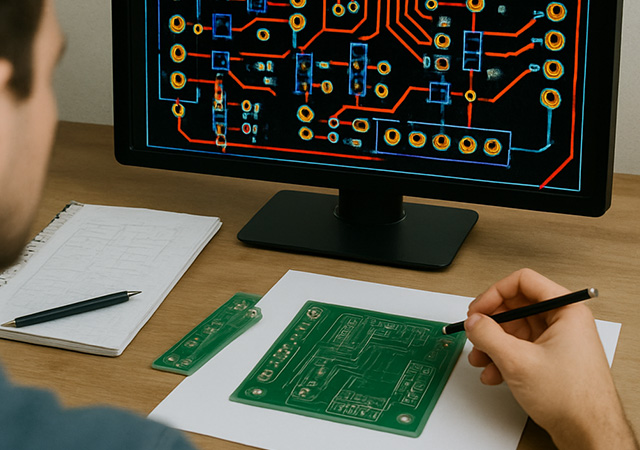

Discover the crucial steps in PCB assembly, from design to final product. Learn how custom PCBs are transformed in this essential process.

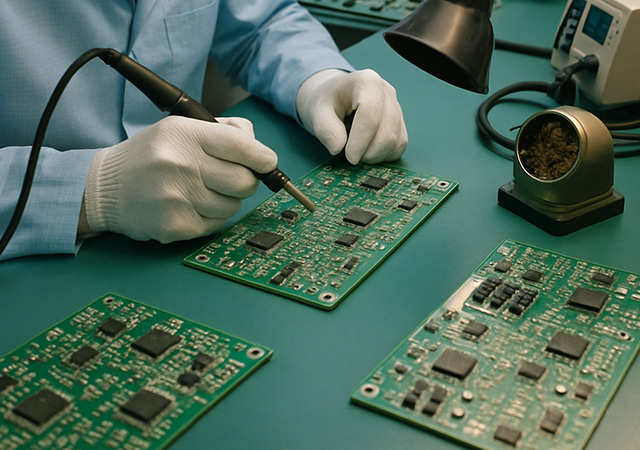

Discover the vital role of PCBA solutions in electronics manufacturing. Learn how efficient PCB design enhances production quality and scalability.

Unlock affordable efficiency with cost-optimized PCBA solutions. Learn to balance quality and cost for enhanced competitiveness in electronics manufacturing.

Unlock innovation with customized PCBA solutions. Tailor your electronics with precise design and performance to gain a competitive edge in the market.

Discover the benefits of flex PCB assembly techniques that enhance electronic device efficiency with improved durability, performance, and cost savings.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB