-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Discover the intricacies of 5G antenna PCB manufacturing, from precise fabrication to advanced assembly services. Explore the future of connectivity today!

Discover how to choose the best PCB manufacturer for your needs, focusing on experience, technology, and quality standards for reliable and efficient results.

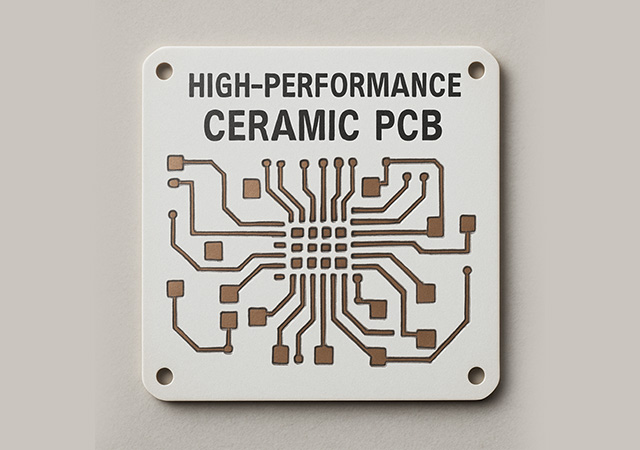

Explore the revolutionary world of high layer count ceramics, their manufacturing processes, and diverse applications in industries like electronics, aerospace, and medical devices.

Discover the benefits of HTCC high layer ceramic substrates in electronics, offering superior thermal stability and mechanical strength for advanced applications.

Discover the advantages of choosing a 12-layer ceramic PCB manufacturer for reliable, high-performance PCB manufacturing services across diverse industries.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB