-

- PCB TYPE

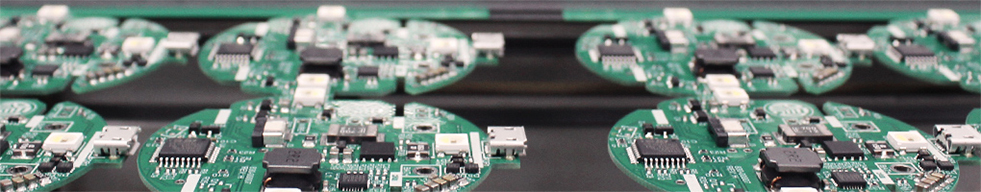

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

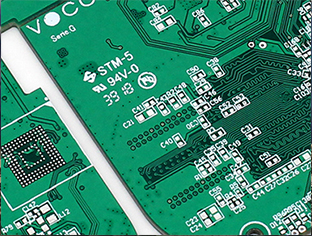

Brand New raw materials such as Rogers, Panasonic, ITEQ, ShengYi, GDM, Nelco, Isola, DuPont,A-level Kingboard (KB)board can be selected according to customer requirements, which are in line with ROHS requirement.

Ink selection: TaiYo/Guangxin/Rongda/Lanbang (the quality of the ink directly affects the solder mask performance of the PCB, and then directly affects the performance of the pcb product)

Chemical Potion : Rohm&Haas (US) Atotech (Germany) Umicore (Germany)

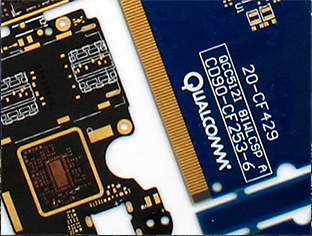

[HAL] The hot air leveling is used to prevent oxidation of the bare copper surface and maintain solderability. As a common form of surface treatment, the quality of the Tin directly affects the welding quality and solderability in subsequent production.

[Immersion Gold] The process is to deposit stable color, good brightness, flat coating, and good solderability on the surface of the printed circuit. The nickel-gold coating is divided into: pre-treatment (degreasing/micro-etching/activation/post-dipping), Immersion of nickel, gold, post-processing

Gold Finger] The process is to cover a thin nickel-gold layer on the copper surface through an electrochemical oxidation-reduction reaction. Advantages: wear resistance, oxidation resistance, low resistance, thick plating control: 0.25-1.5um

AOI automatic optical inspection is based on optical principles, comprehensively using image analysis, computer and automatic control and other technologies to automatically detect and process PCB defects encountered in production, which can efficiently and accurately screen out defective products and avoid The defective PCB flows to the client or the next process.

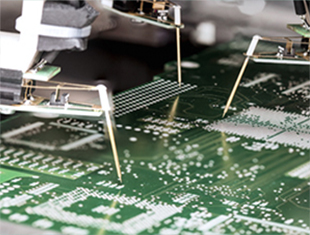

Flying probe test, the test probe moves quickly point by point on the PCB circuit board to complete the test.Each test probe is controlled by the precise transmission system to control the movement position, the position accuracy can reach 0.01mm, and the circuit board with higher density and smaller PAD can be tested.

Manual inspection. The company has a strictly complete quality management system. Each link of production is equipped with professional inspectors. From the IQC inspection of raw materials, to the OQC inspection of the shipment can greatly reduce appearance defects

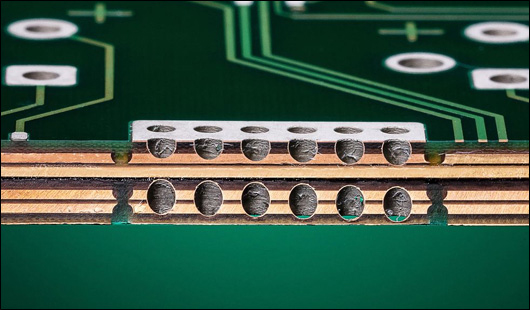

X-RAY inspection equipment can detect the internal structure of ultra-fine pitch and ultra-high-density PCB circuit boards, so as not to damage the PCB,such as bridges, missing pieces, poor alignment, and open circuits.

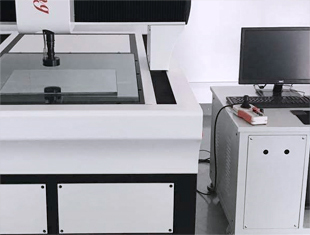

The 2D measurement uses a 2D image measuring instrument to measure the dimensions of the hole position, length, width, and position.It has become the best high-precision size measuring instrument.

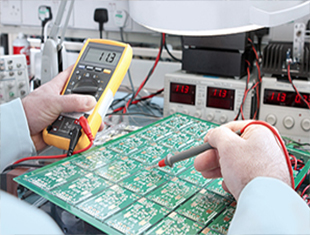

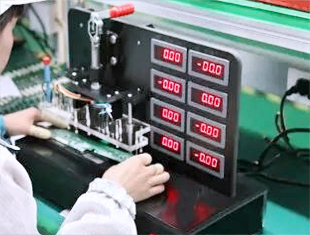

FCT/ICT test, according to the PCB design provided by the customer, including test points, so we build E-test fixture to simulate the input and output of the PCB circuit, and to detect short or open defectives.

Efficient and convenient, shorten the delivery time. Apollopcb not only has professional PCB engineers and business teams to provide quick quotation and proofing, but also a complete PCBA assembly workshop. When you choose to let Apollo do PCB, Apollo can make PCBA quotation and purchase materials at the same time. When PCB production is completed, the materials and fixtures required by PCBA are ready, and they are immediately transferred to PCBA production. The production is closely connected and there is no need to wait for the process.

Improve the service system to ensure service quality. While we continue to upgrade automation equipment, we also pay more attention to enhancing customer experience. After receiving complete information from customers, we can complete PCB quotations as soon as one hour, and provide customers with free pre-production evaluation of manufacturability, design parameters, and process materials. Suggest or improve the plan. During the production process, the sales staff will promptly report the production progress and production status to the customer, so that the customer can control the production without any worries.

The warranty is 2 year, which is rare in the industry. Strictly manage and control in accordance with IPC standards to ensure the qualified rate of shipment quality. If customers use products in a standardized process, non-PCB external factors cause bad problems, Apollo promises free maintenance within one year. All PCB circuit boards are strictly inspected. In addition to manual visual inspection, we use automatic testing and inspection equipment, such as Flying probe tester, X-ray inspection machine, FCT and AOI automatic optical inspection equipment.

• Default process: only 1.6mm plate thickness, lead spray tin, copper thickness 1OZ, green oil white silkscreen

• File format: We only accept DXP, Protel99, PADS, CAM and Gerber files

• Those with special craftsmanship, please be sure to indicate or contact the customer service specialist

• The via process only satisfies round holes, and does not do square holes and other heterogeneous vias

• Except for matt black, matt green and purple, all other colors are free of charge!

• Order payment before 18:00 on the same day, and the delivery period will start from the next day

APOLLOPCB offers 24 hours express to 48 hours express lead time for PCB express fabrication. The normal PCB fabrication time in APOLLOPCB is 2-3 days for 2 layers. If you need it urgently, you could choose the express as your requirement. APOLLOPCB assures that we will arrange your order on time.

We fully stand behind the workmanship and quality of your PCB order within our stated PCB fabrication capabilities, and if you are not satisfied with your order, you could contact us! APOLLOPCB factory is ISO9001 and cURus certified. The quality of your PCB boards is guaranteed.

At APOLLOPCB, all the boards will go through the most stringent tests other than the basic visual check. We adopt most of the testing and inspecting equipment used in the industry, such as Flying Probe Tester, X-Ray Inspection Machine, Automated Optical Inspection (AOI) Machine. We are having 55+ new engineers on the daily basis around the world using our PCBs for their work, who trust us for our reliable quality.

Please Note: Customers need to be careful when you place order online, make sure that the information you have provided is correct and you submit the correct Gerber files to APOLLOPCB for manufacturing. APOLLOPCB is not responsible for boards that fail to function due to wrong order and/or if there are errors in design files submitted by the customer.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB