-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

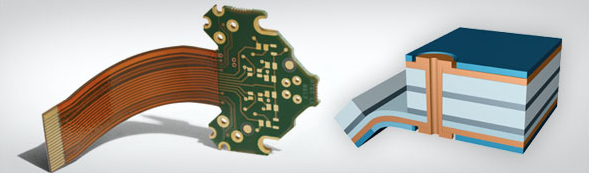

Rigid-flexible printed circuit boards directly combine the advantages of flexible and rigid printed circuit boards. This combination of technologies brings the user a variety of advantages especially in terms of signal transmission, overall size, assembly and stability. APOLLOPCB produces this technology in three of its plants, allowing it to offer a wide range of products and expertise.

In rigid-flexible printed circuit boards, APOLLOPCB offers:

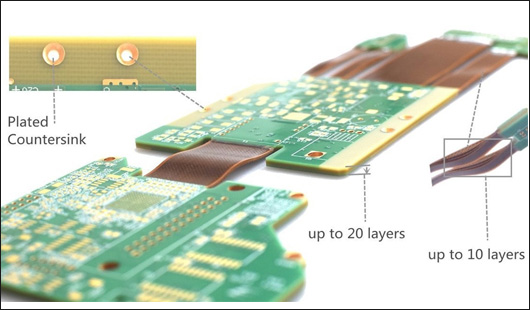

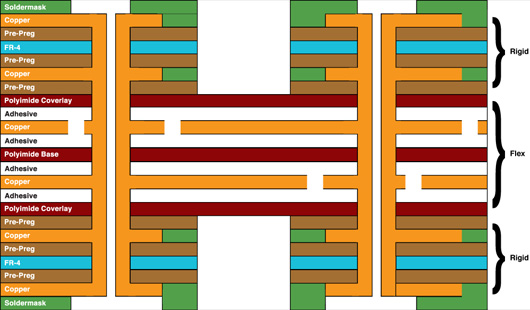

Printed circuit boards with rigid areas, and flexible areas with reduced numbers of layers

Combination of polyimide and FR4, or FR4 and thin laminate

Rigid-flexible printed circuit boards, which connect rigid boards without the need for cables or connectors, resulting in better signal transmission

With SMD population and underfill

All commonly used surfaces available

What are the advantages of the rigid-flex PCBs?

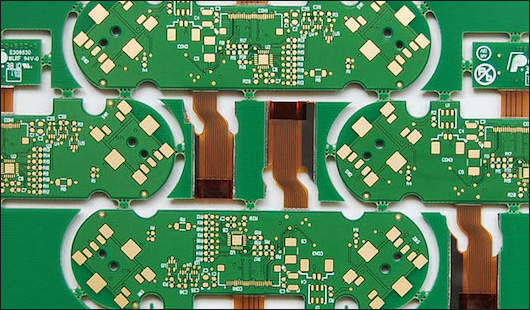

One of the critical characteristics of rigid-flex PCBs is the slim profile and variable shapes, making them ideal solutions for ultra-thin and ultra-light packages. Although the rigid-flex boards may be more expensive in designing and manufacturing, they do have lots of advantages that can solve many problems in traditional hardboard technologies.

1. Compact size and flexible shape

Rigid-flex PCBs are easier to install more components in a smaller space because they can change the shapes according to specific outlines. This technology will reduce the size and weight of the final products and overall system costs. At the same time, the compact profile of rigid-flex PCB makes it the best choice for fine line and high-density circuits in HDI technologies.

2. Customization available for different applications

Rigid-flex PCBs are freedom in packaging geometry and can be tailored for applications in many industries such as aerospace, military, medical equipment, and consumer electrics. They are available to customize the size and shape to fit the housing designs and 3D designs, which provides designers more possibilities to meet different requirements in specific applications.

3. Better mechanical stability

The stability of rigid boards and the flexibility of flexible boards form a stable structure of the entire packages while retaining the reliability of the electrical connection and flexibility needed for installation in small spaces.

4. Better performance under harsh environments

Rigid-flex PCBs have high-shock and high-vibration resistance so that they can work well in high-stress environments. And fewer cables and connectors are used in rigid-flex PCBs, which also reduces safety risks and maintenance in future use.

5. Easy to be fabricated and tested

Rigid-flex PCBs require less number of interconnectors and related components/parts. It helps to simplify the assembly operations, making the rigid-flex PCBs are easier to be assembled and tested. Rigid-flex PCBs are very suitable for PCB Prototypes.

Besides the benefits mentioned above, other common advantages of rigid-flex PCBs include high circuit density, excellent thermal dissipation and chemical resistance, etc. All in all, rigid-flex PCBs combine all the benefits of hard PCB and flexible PCB while complementing the disadvantages. This kind of PCBs is an optimal solution to design reliable and robust circuits for smart wearable devices and other industries. APOLLOPCB has a strict quality control system to ensure the rigid-flex boards manufactured and assembled correctly with high-quality standards. If you need more details like quotation or order, contact us via info@apollopcb.com now.

Get Rigid-flex PCBs Fabrication

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB