-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

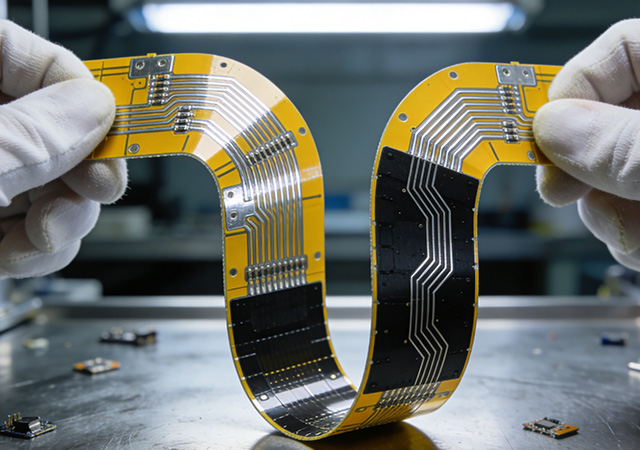

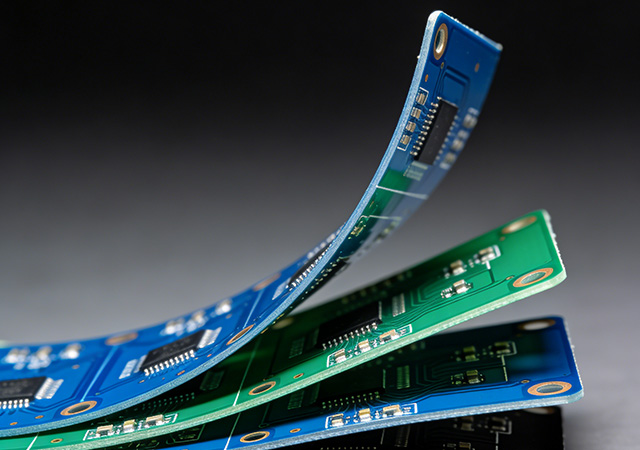

As the global electronics industry shifts toward miniaturization, intelligence, and multi-scenario adaptation, flexible PCB has evolved from a supporting component in consumer electronics to a core enabler of cross-sector innovation. Beyond its inherent advantages of thinness, light weight, and bendability, modern flexible PCB is driving a dual-wheel growth pattern centered on consumer electronics and automotive electronics, while penetrating emerging fields such as AR/VR and industrial control. Unlike rigid PCBs or early flexible circuits, today’s advanced flexible PCB integrates high-performance materials, precision manufacturing, and modular design, meeting the stringent requirements of diverse high-end applications. For electronic manufacturers, grasping the technological evolution and application expansion of flexible PCB is crucial to seizing market opportunities in the era of electronic industry upgrading.

As LED lighting technology evolves toward versatility, intelligence, and aesthetic integration, LED Lighting Flexible PCB has become a foundational component in modern illumination systems. This specialized circuit solution combines the inherent flexibility of flexible PCBs with tailored designs for LED lighting applications, addressing core demands such as easy installation, uniform light distribution, and compatibility with smart control systems. Unlike generic flexible PCBs or rigid alternatives, LED Lighting Flexible PCB is engineered to adapt to diverse lighting scenarios—from residential decoration to commercial signage and automotive ambient lighting—while ensuring energy efficiency and long-term reliability. For lighting manufacturers, adopting high-quality LED Lighting Flexible PCB is key to unlocking innovative product designs and meeting the evolving needs of both residential and industrial lighting markets.

As high brightness LED (HBLED) technology penetrates commercial lighting, stage illumination, and high-definition display sectors, the demand for High Brightness LED Flex PCB has escalated rapidly. This specialized circuit solution integrates light efficiency enhancement, precise thermal management, and advanced packaging technologies, addressing the core challenges of HBLED systems—such as heat accumulation and light loss—while leveraging the flexibility and compactness of flexible PCBs. Unlike standard LED flex PCBs designed for general illumination, High Brightness LED Flex PCB is engineered to maximize luminous efficiency, ensure long-term stability under high-power operation, and enable creative lighting designs. For lighting manufacturers, adopting high-performance High Brightness LED Flex PCB is pivotal to delivering high-lumen, energy-efficient lighting solutions and expanding into premium market segments.

As LED lighting expands into outdoor, marine, automotive, and high-humidity applications, the demand for Waterproof LED Flexible PCB has surged. This specialized circuit solution integrates robust waterproofing technologies with the inherent flexibility and compactness of flexible PCBs, ensuring stable performance of LED systems in moisture, dust, and corrosive environments. Unlike standard flexible PCBs that lack environmental resistance, Waterproof LED Flexible PCB leverages advanced coating, encapsulation, and material optimization to protect LED components and circuit traces from water intrusion and degradation. For lighting manufacturers, adopting high-quality Waterproof LED Flexible PCB is critical to enhancing product durability, reducing maintenance costs, and unlocking new application possibilities in extreme illumination scenarios.

As the global electronics industry marches toward miniaturization, intelligence, and eco-friendliness, flexible PCB has evolved from a supporting component to a core enabler of technological innovation. Beyond its traditional advantages of thinness, light weight, and bendability, modern flexible PCB is driving breakthroughs in material science, sustainable manufacturing, and niche high-end applications. Unlike conventional rigid PCBs and early flexible circuits, today’s advanced flexible PCB integrates novel materials such as liquid metals and recyclable polymers, addressing critical challenges in stretchability, durability, and environmental impact. For electronics manufacturers and designers, understanding these emerging trends in flexible PCB is essential to unlocking new product possibilities and gaining a competitive edge in fast-evolving markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB