-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

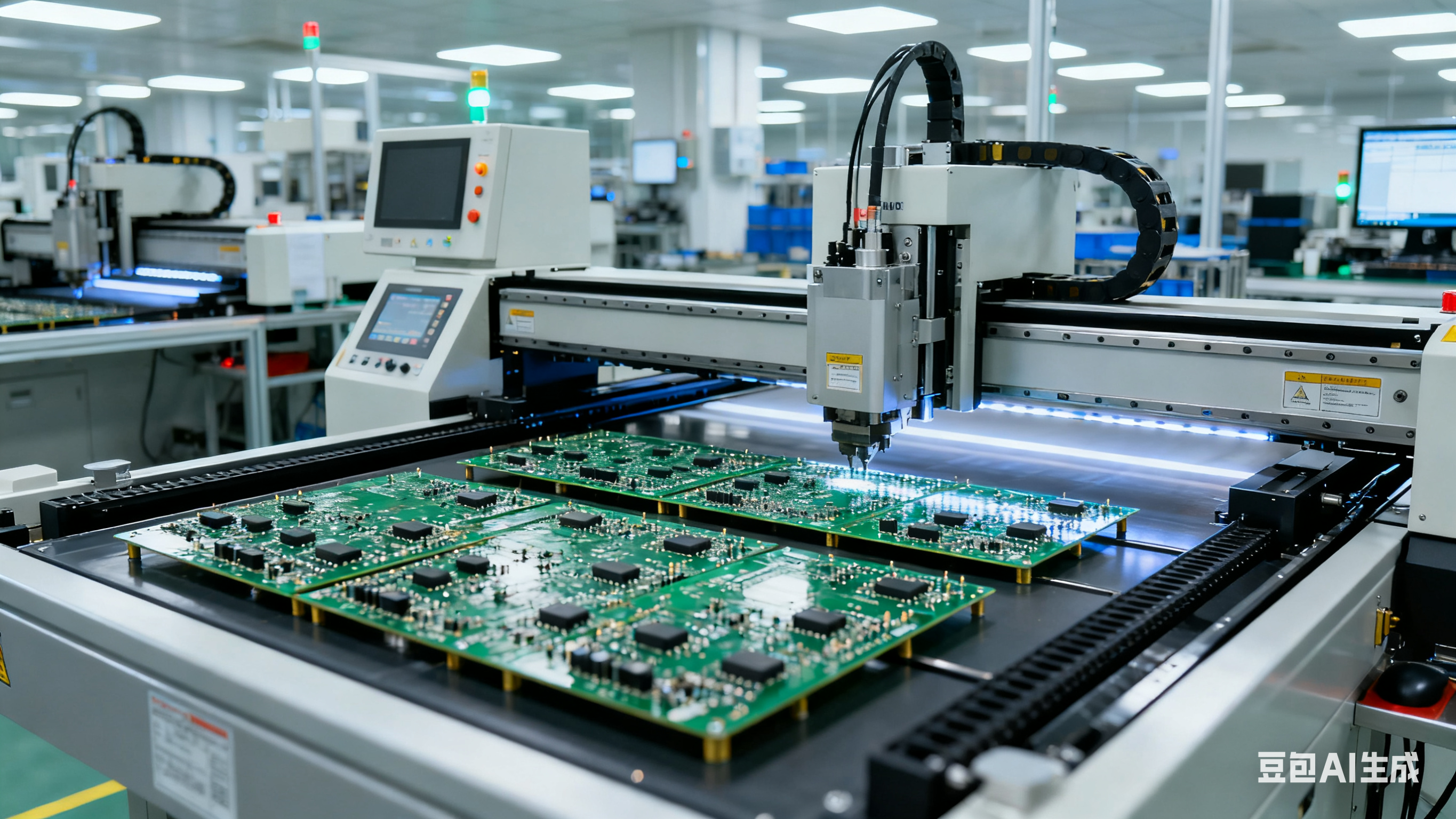

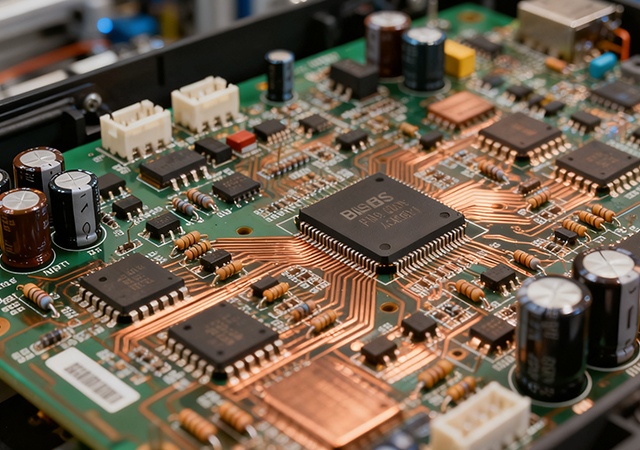

PCB Assembly remains the backbone of modern electronics, transforming bare circuit boards into functional components that power everything from smart appliances to aerospace systems. As technology evolves at an unprecedented pace, PCB assembly has shifted from a purely technical process to a strategic discipline—integrating emerging technologies, prioritizing quality at every stage, and building resilience against global disruptions. Today’s manufacturers must balance precision, speed, and adaptability to meet the demands of sectors like 5G, electric vehicles (EVs), and edge computing. This article explores the latest trends shaping PCB assembly, innovative quality assurance practices, and how the industry is fortifying itself against challenges, ensuring reliable production in a dynamic landscape.

Turnkey PCB Assembly has emerged as a transformative solution in electronics manufacturing, offering businesses a seamless, single-source approach to bringing PCB designs from concept to finished product. Unlike fragmented manufacturing models—where clients juggle component sourcing, assembly, testing, and logistics across multiple vendors—turnkey services consolidate every stage under one provider. This integration eliminates operational silos, reduces administrative burdens, and aligns production with business goals, whether that’s faster time-to-market, improved quality, or scalable growth. For companies navigating global supply chain complexities and evolving technical demands, turnkey PCB assembly is no longer a convenience but a strategic imperative to stay competitive.

Cost-Effective Turnkey PCB Assembly redefines value in electronics manufacturing by delivering end-to-end assembly services that prioritize budget efficiency without compromising quality or performance. Unlike generic turnkey solutions that may overcharge for unnecessary features, this specialized approach focuses on targeted cost optimization—aligning production processes, supply chain strategies, and service scopes with a client’s specific budget and technical needs. For businesses ranging from startups to mid-sized enterprises, cost-effective turnkey assembly eliminates the hidden expenses of fragmented production (e.g., component markup, rework costs, logistics delays) while ensuring reliable, compliant PCBs. This article explores the core strategies behind cost-effective turnkey services, their industry-specific applications, quality safeguards, and how they drive competitive advantage in price-sensitive markets.

Full-Service Turnkey PCB Assembly represents a comprehensive, end-to-end solution that simplifies electronics manufacturing by integrating every stage of PCB production—from design validation and component sourcing to assembly, testing, and final delivery. Unlike traditional PCB assembly services that require clients to manage fragmented processes (e.g., sourcing parts, coordinating with multiple vendors), turnkey solutions place full responsibility in the hands of a single provider. This approach is a game-changer for businesses of all sizes, from startups with limited engineering resources to multinational corporations seeking to optimize efficiency. By offering a “one-stop shop” experience, full-service turnkey PCB assembly reduces lead times, minimizes supply chain risks, and ensures alignment with industry standards—all while letting clients focus on core innovation rather than production logistics.

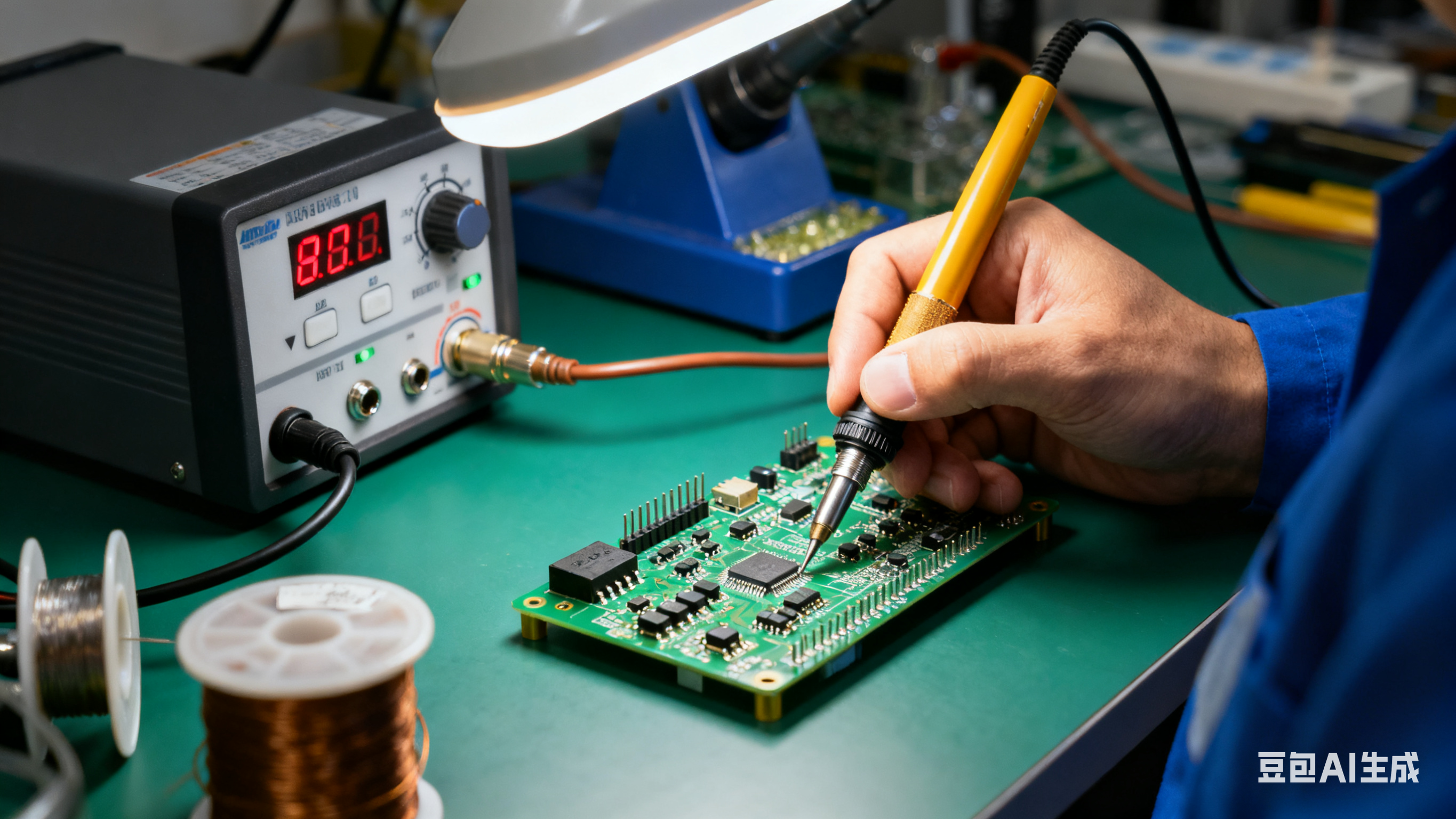

PCB Assembly is the critical bridge between printed circuit board (PCB) design and functional electronic devices, encompassing the integration of components—from resistors and capacitors to advanced semiconductors—onto PCBs. As the backbone of electronics manufacturing, this process balances precision, efficiency, and reliability to meet the demands of diverse sectors, from medical devices to telecommunications. Unlike PCB fabrication (which focuses on creating the bare board), PCB assembly transforms empty substrates into operational circuits, requiring mastery of both traditional and cutting-edge techniques. This article explores the foundational processes of PCB assembly, its tailored adaptations across industries, key quality control measures, and emerging trends shaping its evolution.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB