-

- PCB TYPE

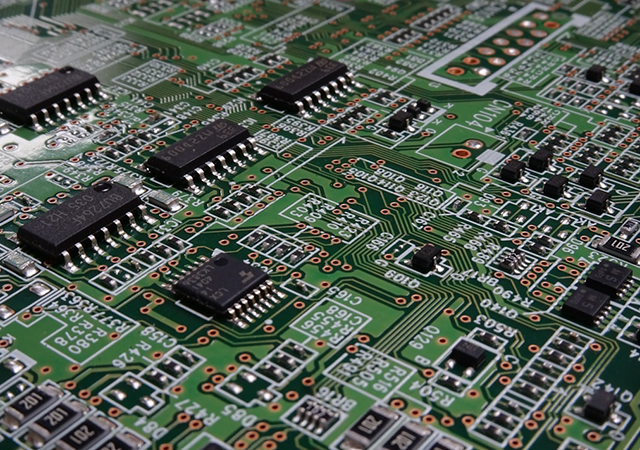

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

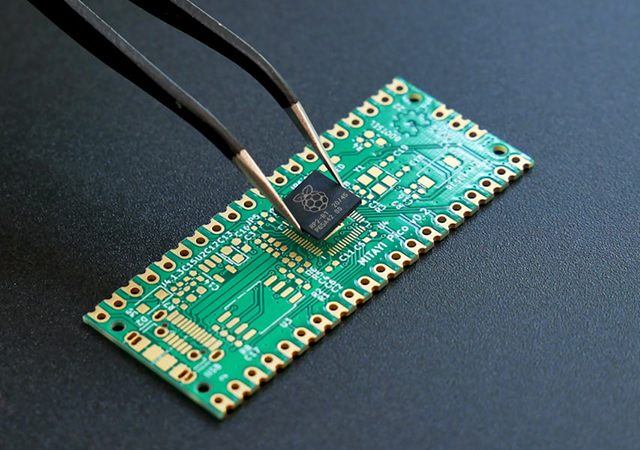

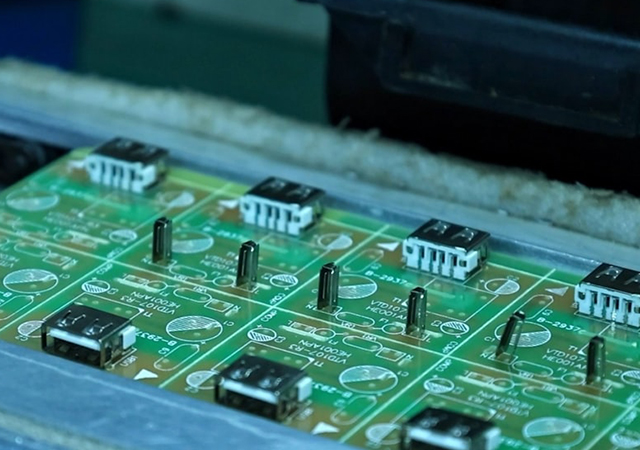

Discover how the high-speed SMT assembly process transforms electronics manufacturing with enhanced speed, precision, and flexibility.

Explore the intricate steps of the PCB assembly process, from PCB design to manufacturing, to enhance your electronics expertise and improve project outcomes.

Discover how Electronics Manufacturing Services (EMS) can transform your business with cost-effective solutions, expertise, and precision in PCB assembly.

Discover reliable high-quality electronics manufacturing services tailored to your needs. Enhance product quality, cost efficiency, and market speed with expert EMS providers.

Streamline production with one-stop electronics manufacturing services. From design to delivery, simplify processes, enhance quality, and reduce costs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB