-

- PCB TYPE

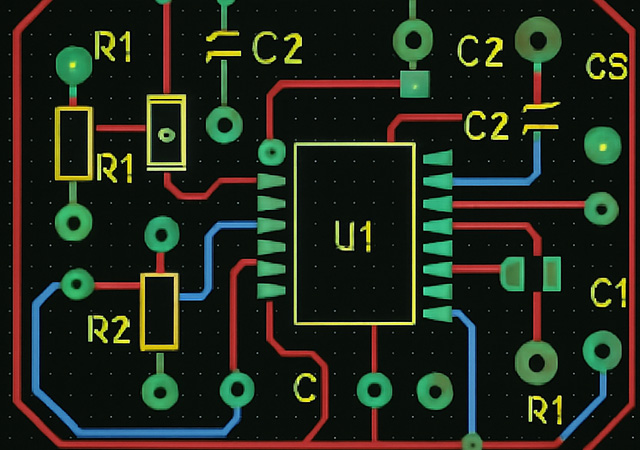

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

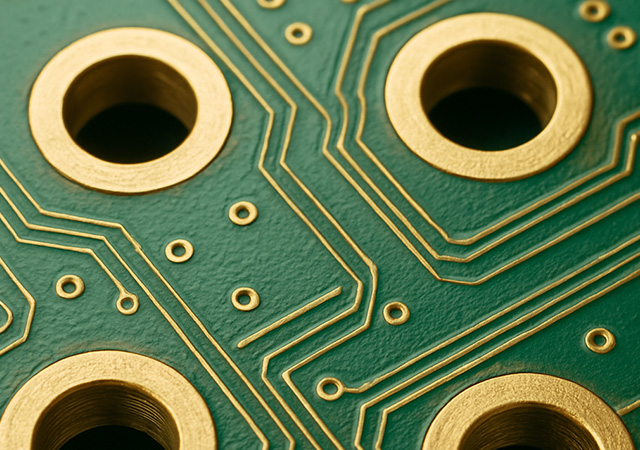

Discover precision and efficiency with our comprehensive guide on choosing a reliable tapped counterbore PCB supplier for all your electronics manufacturing needs.

Find the best 3mm counterbore PCB manufacturer to ensure quality and precision. Discover benefits of counterbore holes and reliable PCB manufacturing solutions.

Find the perfect PCB manufacturer for custom PCB and assembly needs. Prioritize quality, cost, and expertise to ensure timely, top-notch electronic projects.

Discover how a leading countersink holes PCB manufacturer utilizes advanced techniques to enhance PCB design, aesthetics, and structural integrity.

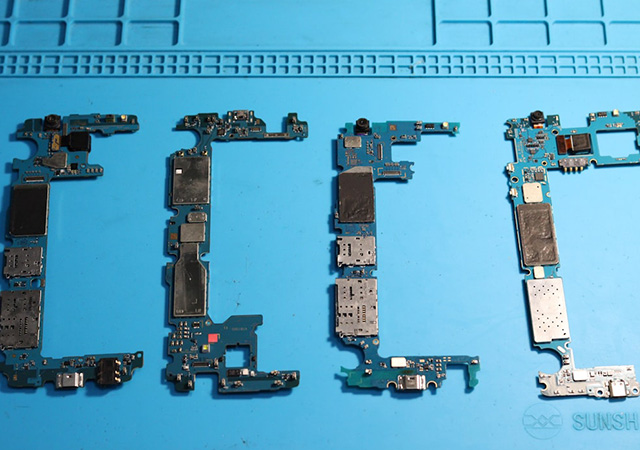

Discover expert countersink holes PCB manufacturing in China. Learn the process, benefits, and how to select the right factory for efficient, cost-effective production.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB