-

- PCB TYPE

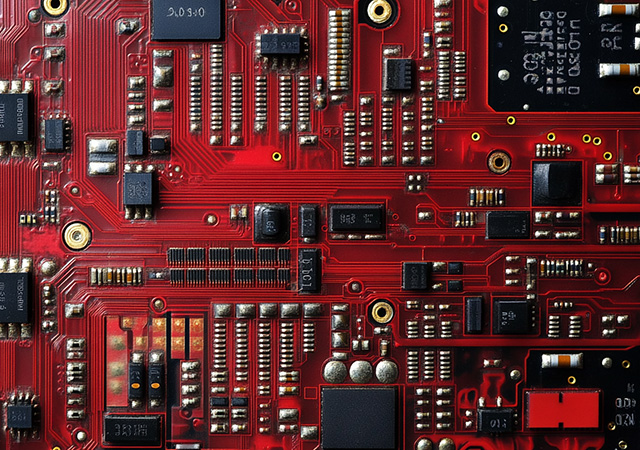

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Explore the benefits of high CTI value CEM3 PCBs for enhanced safety, reliability, and cost-effectiveness in electronic devices. Perfect for diverse applications!

Explore the benefits of CTI 600 CEM3 PCB substrate, a top choice in PCB manufacturing for its high CTI value, superior insulation, and versatile applications.

Discover the benefits of high CTI CEM3 material with a 600V rating, ideal for safe and reliable high-voltage applications in electronics and automotive industries.

CEM3 PCB has evolved beyond traditional mid-tier electronics to become a cornerstone of emerging technologies, offering a unique blend of mechanical robustness, dielectric stability, and cost efficiency that bridges basic substrates and high-end materials. Unlike specialized PCBs limited to niche uses, CEM3 PCB’s adaptability makes it indispensable in rapidly growing sectors such as 5G infrastructure, smart healthcare devices, and sustainable energy systems.Modern electronics demand substrates that can handle mixed-signal environments, harsh operating conditions, and miniaturized designs—requirements that generic CEM1 or even standard FR4 often fail to meet without excessive cost. CEM3 PCB addresses this by integrating advanced material formulations and design flexibility, enabling it to support higher power densities, faster signal speeds, and longer lifespans in diverse applications.This article explores CEM3 PCB’s role in emerging industries, material innovations enhancing its perfo

LED light CEM3 represents a synergistic integration of CEM3 substrate technology with LED lighting systems, offering a balanced solution for modern illumination needs. Unlike generic substrates that prioritize either cost or performance, LED light CEM3 is engineered to address the unique demands of LED-based lighting—sustained thermal management, consistent light output, and resilience across diverse environments—while remaining cost-effective for mass deployment. This makes it a cornerstone in applications ranging from residential downlights and commercial panel lights to industrial floodlights and outdoor street lamps.LED lighting systems rely on stable substrates to maintain performance over their 50,000+ hour lifespan. Traditional materials often fall short: basic CEM1 boards struggle with heat buildup in high-power LEDs, while metal-core PCBs (MCPCBs) add unnecessary cost for mid-tier applications. LED light CEM3 resolves this by combining enhanced thermal conductivity, dielectric

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB