-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

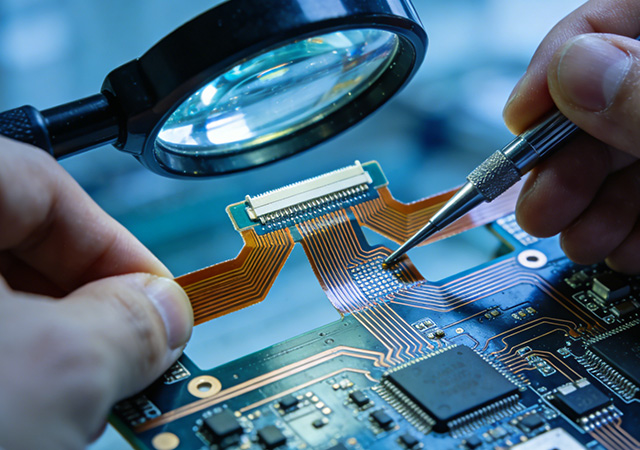

In the competitive landscape of flexible electronics, the quality and consistency of Flexible Printed Circuit Boards (FPCBs) directly determine the performance and market competitiveness of end products. For businesses seeking to mitigate risks and ensure stable supply chains, partnering with an ISO 9001 Certified FPCB Supplier has become a strategic imperative. ISO 9001 certification, a globally recognized benchmark for quality management systems, signifies that a supplier adheres to rigorous standards of process control, quality assurance, and continuous improvement. This certification is not merely a label; it is a guarantee that the FPCB supplier can consistently deliver high-quality products that meet customer requirements and industry regulations, making it an indispensable partner for industries ranging from consumer electronics to automotive and industrial automation.

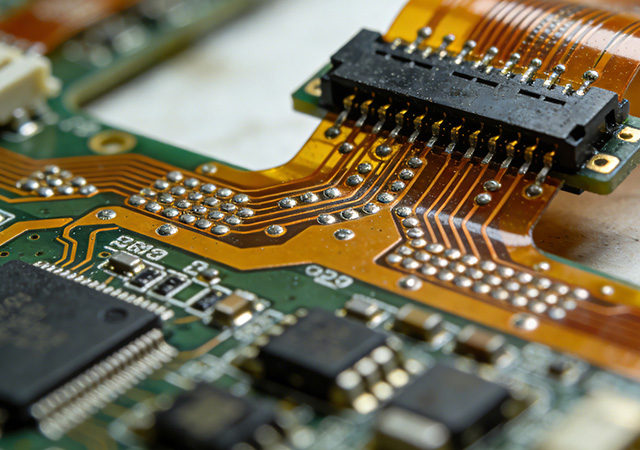

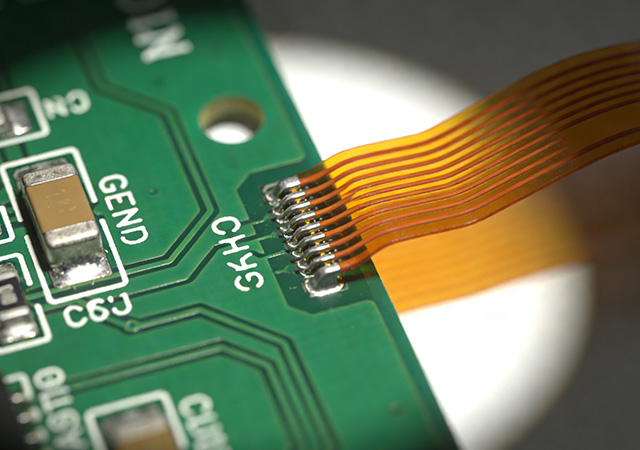

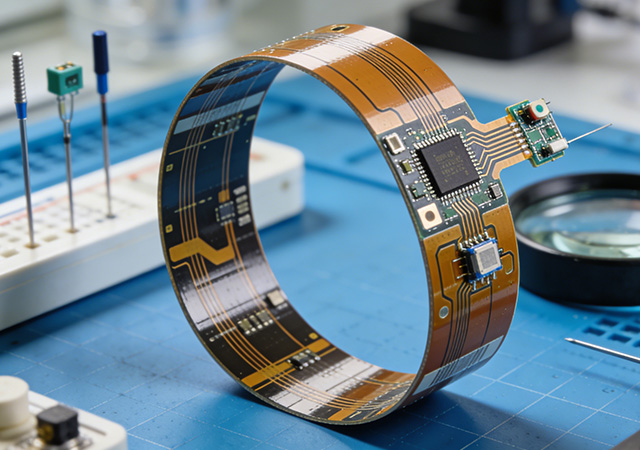

In the era of smart, compact, and multi-functional electronics, Flexible Printed Circuit Boards (FPCB) have emerged as a transformative technology, redefining the boundaries of device design and performance. Unlike traditional rigid printed circuit boards (PCBs), FPCB leverages flexible substrate materials to deliver unparalleled adaptability, enabling electronic components to fit into curved, confined, or irregular form factors. As industries ranging from consumer tech to automotive and healthcare pursue innovation, FPCB has become a core enabler, powering products that are lighter, thinner, and more reliable. The unique combination of flexibility, miniaturization, and electrical stability makes FPCB a cornerstone of modern electronics, driving advancements that were once deemed impossible.

As the electronics industry evolves toward miniaturization, portability, and versatility, flexible printed circuit boards (FPCBs) have become a staple in modern device design. At the heart of bringing these flexible components to life lies FPCB Assembly—a specialized process that combines precision engineering with adaptive manufacturing to ensure FPCBs deliver reliable performance across diverse applications. FPCB Assembly is not merely a production step; it is a critical enabler of innovation, allowing engineers to translate bold design concepts into functional products that shape industries from consumer tech to automotive and industrial automation. In a market where device functionality and form factor are key differentiators, the quality and efficiency of FPCB Assembly directly impact a product’s success.

The healthcare industry stands at the forefront of technological innovation, with electronic devices playing an increasingly pivotal role in diagnosis, treatment, and patient care. From portable diagnostic tools to implantable medical devices, these innovations rely on components that meet the most stringent standards of precision, reliability, and biocompatibility. Among these critical components, flexible printed circuit boards (FPCBs) have become indispensable, and Medical Grade FPCB Assembly Solutions emerge as a cornerstone to ensure these boards meet the unique demands of the healthcare sector. Unlike standard FPCB assembly services, Medical Grade FPCB Assembly Solutions are engineered to adhere to rigorous regulatory frameworks and clinical safety requirements, making them essential for advancing life-saving medical technologies.

In the fast-paced electronics industry, where product lifecycles are shrinking and market competition is intensifying, the ability to bring new products to market quickly has become a decisive competitive advantage. For businesses developing flexible electronic devices, Quick Turn FPCB Assembly Service emerges as a critical enabler, bridging the gap between design validation and mass production with efficient, timely assembly solutions. This specialized service not only shortens lead times but also ensures that flexible printed circuit boards (FPCBs) meet the rigorous performance requirements of diverse applications, from consumer gadgets to medical devices and automotive electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB