-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

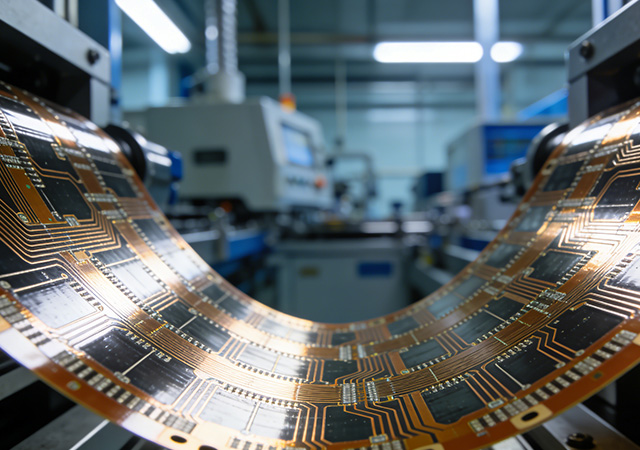

In the fast-paced landscape of technological innovation, where market windows close rapidly and product iteration cycles shrink constantly, Quick Turn Customize Flexible Circuit Service has emerged as a game-changing enabler for tech pioneers. Unlike traditional flexible circuit services that prioritize mass production over speed and customization, this specialized service combines rapid turnaround capabilities with tailored solutions, addressing the core pain points of startups, research institutions, and enterprises pursuing agile product development. By delivering customized flexible circuits in shortened timeframes without compromising quality, Quick Turn Customize Flexible Circuit Service empowers innovators to validate design concepts swiftly, iterate on prototypes efficiently, and seize market opportunities before competitors—solidifying its role as a critical pillar of the modern tech innovation ecosystem.

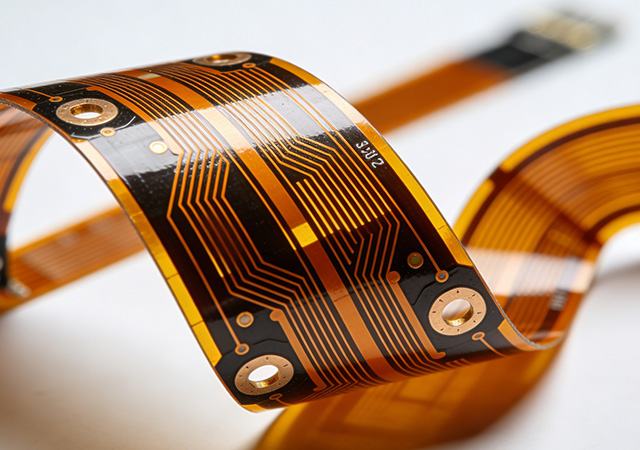

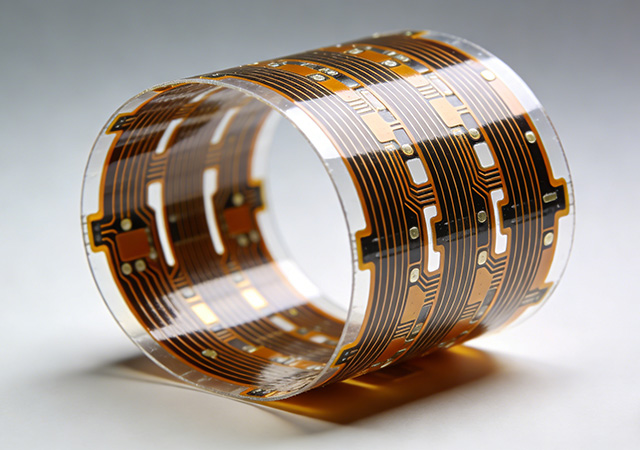

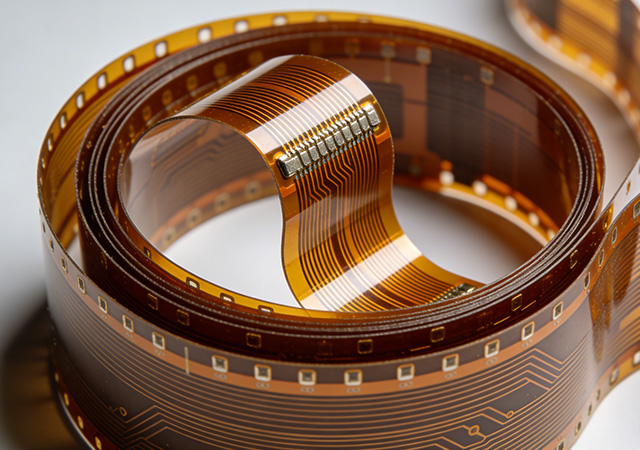

In the era of electronic innovation dominated by miniaturization, intelligence, and adaptability, FPCB (Flexible Printed Circuit Board) has evolved from a supporting component to a core connector that underpins the entire flexible electronics ecosystem. Unlike rigid PCBs that limit product form and application scenarios, FPCB’s unique flexibility, lightweight nature, and reliable electrical performance have broken through traditional design boundaries. It serves as a critical bridge between electronic components, enabling seamless integration of diverse technologies in fields such as consumer electronics, industrial IoT, and smart healthcare. As global demand for flexible, portable, and intelligent electronic products surges, FPCB’s role in driving industry upgrading and technological innovation becomes increasingly irreplaceable.

In the rapidly evolving electronics industry, the demand for personalized, application-specific components has driven the rise of customize FPCB as a core enabler of product innovation. Unlike standard off-the-shelf FPCBs that impose design limitations, customize FPCB offers tailored solutions that align with the unique spatial constraints, performance requirements, and functional goals of diverse electronic products. From compact wearable devices to complex industrial control systems, customize FPCB empowers engineers and designers to translate creative concepts into practical, high-performance products. Its ability to adapt to varied industry needs has made it a cornerstone of modern electronic development, helping brands gain a competitive edge in crowded markets.

In the era of high-end electronics pursuing extreme performance and environmental adaptability, Polyimide Customize FPCB Solution has emerged as a core enabler for technological innovation. Polyimide, known as the "golden film" in the electronic material field, boasts exceptional thermal stability, electrical insulation, and environmental resistance. Combined with customized flexible printed circuit board (FPCB) design, this solution effectively addresses the pain points of traditional FPCB materials that struggle to withstand harsh conditions such as high temperatures, strong radiation, and chemical corrosion. From aerospace equipment operating in extreme cosmic environments to precision medical devices requiring long-term stable operation, Polyimide Customize FPCB Solution provides tailored, high-reliability circuit solutions, becoming an indispensable cornerstone for high-end electronic products.

In the fast-paced electronic product development landscape, the ability to quickly validate design concepts and respond to market changes has become a key competitive advantage. Quick Turn Customize FPCB Service emerges as a critical enabler, addressing the core pain points of long lead times and inflexible solutions in traditional FPCB manufacturing. This service combines rapid turnaround capabilities with tailored design support, allowing electronic manufacturers and R&D teams to obtain customized flexible printed circuit boards (FPCBs) in a shortened timeframe without compromising quality. From small-batch prototyping to urgent production needs, Quick Turn Customize FPCB Service empowers innovators to accelerate product development cycles, reduce time-to-market, and gain an edge in the highly competitive electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB