-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

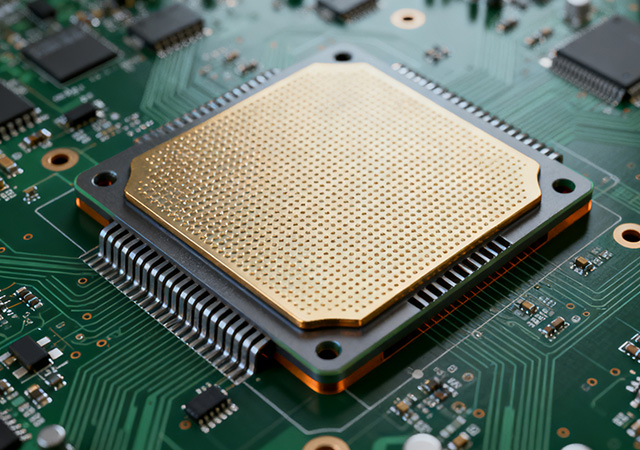

Sinkpad PCB has emerged as a critical enabler for next-generation electronic systems, addressing the growing demand for efficient thermal management and reliable performance in high-power, high-frequency applications. Unlike standard PCBs, sinkpad designs integrate a dedicated metal core (or enhanced thermal layer) that facilitates rapid heat dissipation while maintaining structural integrity—making them indispensable in industries ranging from 5G telecommunications to electric vehicles (EVs) and renewable energy systems. As electronic devices continue to shrink in size while delivering higher power outputs, sinkpad PCBs have evolved beyond basic thermal solutions to incorporate material innovations, electromagnetic compatibility (EMC) enhancements, and sustainable design practices. This article explores the expanding application landscape, material advancements, EMC optimization strategies, and sustainability trends shaping the future of sinkpad PCB technology.

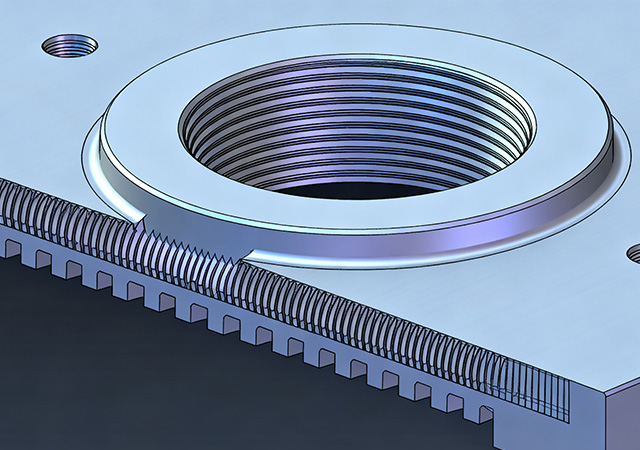

Counterbore holes stand as a foundational element in sinkpad PCB design, enabling the critical balance between mechanical stability and thermal efficiency required for high-power electronic systems. Unlike traditional through-holes or countersunk designs, counterbore holes feature a flat-bottomed cylindrical recess that accommodates fastener heads while preserving the integrity of the sinkpad’s metal core. This design is indispensable in applications where component mounting must not compromise heat dissipation—from industrial power converters to advanced medical devices. By addressing the dual challenges of secure fixation and unobstructed thermal transfer, counterbore holes have become a staple in modern PCB engineering, particularly as electronics trend toward higher power densities and compact form factors. This article explores the core design principles, manufacturing considerations, performance optimization strategies, and emerging trends of counterbore holes in sinkpad PCBs.

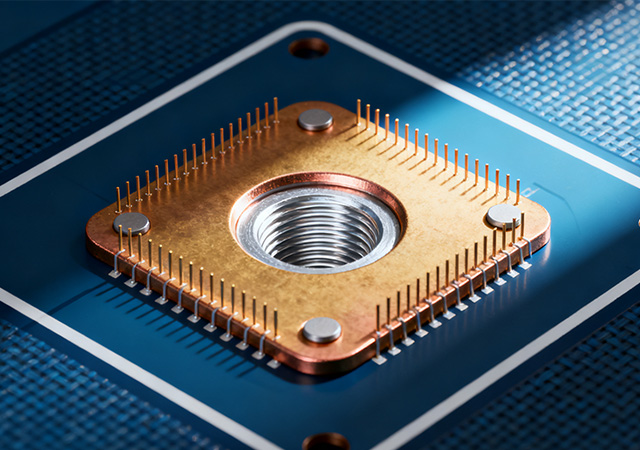

Tapped Counterbore Sinkpad Design redefines secure mounting for high-power electronics by integrating precision-threaded cylindrical recesses with the thermal efficiency of sinkpad technology. Unlike standard counterbore sinkpads that rely on external nuts or adhesive fixation, tapped counterbores feature internal threads (typically M2-M3 for compact applications) directly machined into the sinkpad’s metal core—enabling direct, nut-free fastening of components. This innovative design resolves a critical pain point in compact high-power systems: achieving vibration-resistant component retention without compromising thermal conductivity or increasing assembly volume. By unifying threaded mechanical fixation and contiguous thermal transfer, tapped counterbore sinkpads excel in applications demanding repeated assembly/disassembly, space constraints, and rugged operating conditions—from portable industrial tools to aerospace microsystems. This article explores the core design synergies, per

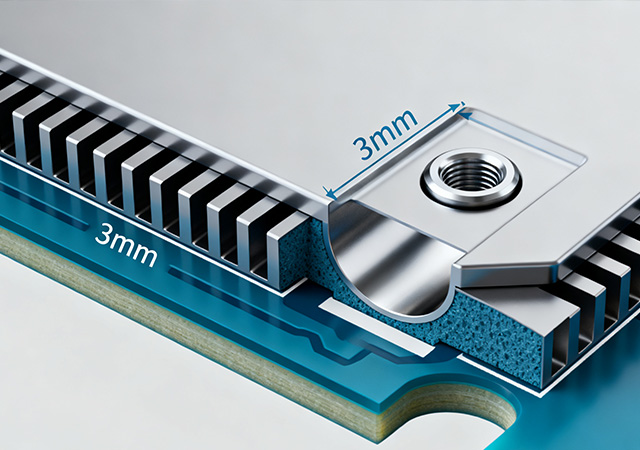

3mm Counterbore Sinkpad PCB emerges as a specialized solution for miniaturized high-power electronics, combining the structural stability of flat-bottomed counterbore holes with the thermal efficiency of sinkpad technology. Unlike tapered countersink designs that prioritize surface flushness, 3mm counterbores feature cylindrical recesses with straight walls and flat bases—engineered to accommodate socket head cap screws, hex bolts, and heavy components requiring robust mechanical fastening. This unique geometry addresses a critical gap in compact electronics: maintaining reliable thermal transfer while supporting secure, vibration-resistant mounting in space-constrained environments. For applications ranging from miniature industrial controllers to portable medical devices, the 3mm dimension strikes an optimal balance between fastening strength, thermal performance, and design miniaturization. This article explores the precision design principles, performance advantages, targeted use c

Sinkpad PCB has evolved into a critical enabling technology for electronics operating in extreme conditions—where traditional PCBs fail to balance thermal management, structural integrity, and environmental resilience. Unlike standard sinkpad designs optimized for controlled environments, adaptive sinkpad PCBs are engineered to withstand harsh stressors: extreme temperature fluctuations, corrosive atmospheres, high vibration, and radiation exposure. These environments—ranging from deep-sea sensors to desert industrial plants, and from aerospace payloads to nuclear power control systems—demand PCB solutions that go beyond basic heat dissipation to deliver multi-faceted environmental resistance. This article explores the core adaptive design strategies of sinkpad PCBs for extreme conditions, environment-specific applications, material - 工艺 innovations, and performance validation frameworks that define their reliability in harsh scenarios.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB