-

- PCB TYPE

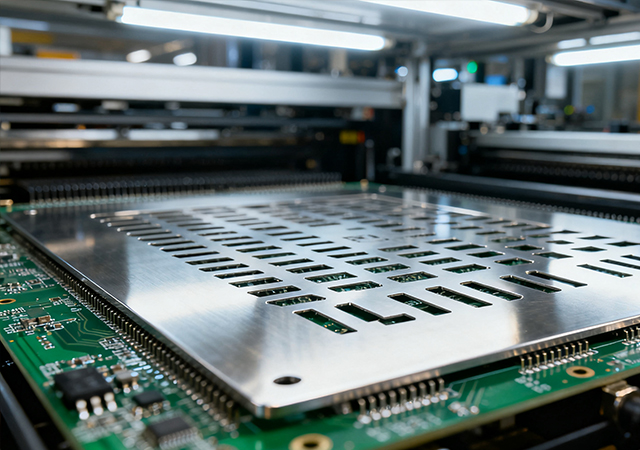

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

China PCB Assembly has evolved from a global manufacturing workhorse to a catalyst for technological innovation, leveraging advanced engineering capabilities and agile market responsiveness to serve the world’s most demanding electronics sectors. Beyond scale and cost efficiency, Chinese PCB assemblers now lead in developing solutions for complex, high-performance applications—from 5G base stations and autonomous vehicles to medical imaging devices. Their unique strength lies in end-to-end innovation integration: combining cutting-edge assembly technologies, close collaboration with chip designers, and flexible production models to turn emerging tech concepts into mass-produced realities. As global industries race toward digital transformation and smartification, China PCB Assembly has become a strategic partner for businesses seeking to stay at the forefront of innovation. This article explores its technical breakthroughs, green manufacturing转型 (transformation), global market alignmen

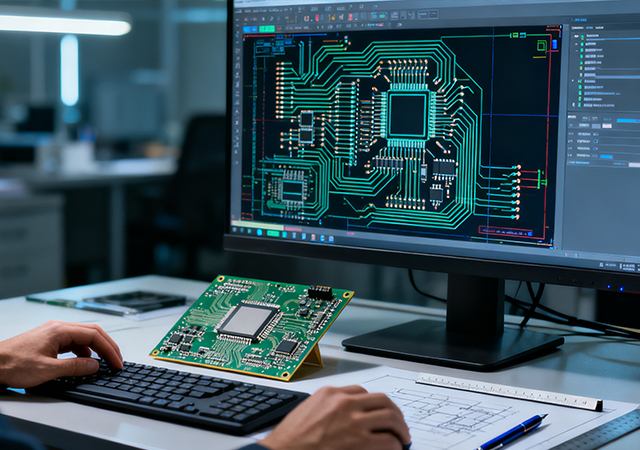

PCB Assembly is no longer a linear post-design process but a collaborative ecosystem where design and production teams work in lockstep to accelerate innovation and cut time-to-market. In today’s fast-paced electronics industry, delays caused by poor design-manufacturing alignment—such as unproducible layouts or last-minute component substitutions—can cost businesses millions in lost market share. The new paradigm of design-production synergy integrates PCB design decisions with assembly feasibility from day one, leveraging digital tools, cross-functional communication, and iterative feedback to create a seamless workflow. This approach not only reduces rework and production bottlenecks but also ensures assemblies are optimized for both performance and manufacturability. This article explores how design-production synergy redefines PCB assembly, its key enablers, industry-specific outcomes, and its impact on competitive advantage.

Low-Cost China PCB Assembly has long been a cornerstone for businesses worldwide seeking to optimize manufacturing budgets without compromising core quality. Unlike generic "budget" assembly services that cut corners on materials or compliance, reputable low-cost Chinese PCB assemblers leverage unique market advantages—supply chain density, economies of scale, and lean production—to deliver cost-efficient solutions for cost-sensitive applications. These services cater to a wide range of clients, from startups testing prototype iterations to SME scaling production of consumer electronics, industrial sensors, and IoT devices. The key distinction of low-cost China PCB assembly lies in strategic cost optimization: reducing unnecessary expenses (e.g., redundant logistics, over-spec’d materials) while upholding critical quality standards and delivery timelines. This article explores the drivers of cost efficiency, quality safeguards, target applications, and how these services add value to g

A China-Based PCB Assembly Supplier stands as a cornerstone of the global electronics manufacturing ecosystem, leveraging unique advantages in supply chain integration, scalable production, and technical agility to serve clients worldwide. Unlike regional suppliers, Chinese PCB assembly partners benefit from proximity to the world’s largest electronics component manufacturing hub—enabling faster sourcing, cost-effective production, and seamless collaboration with upstream material providers. Beyond cost competitiveness, top China-based suppliers have evolved to prioritize precision, compliance, and customer-centric flexibility, catering to diverse sectors from consumer electronics to industrial IoT and new energy. As global demand for customized, high-quality PCBs grows, these suppliers have become strategic partners for businesses seeking to balance speed-to-market, reliability, and scalability. This article explores the core strengths of China-based PCB assembly suppliers, their glob

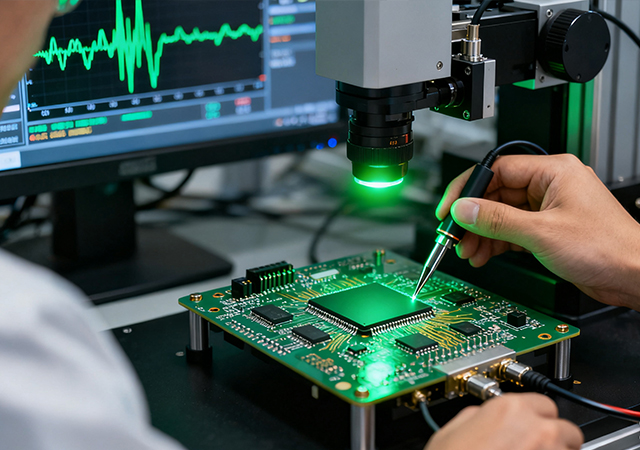

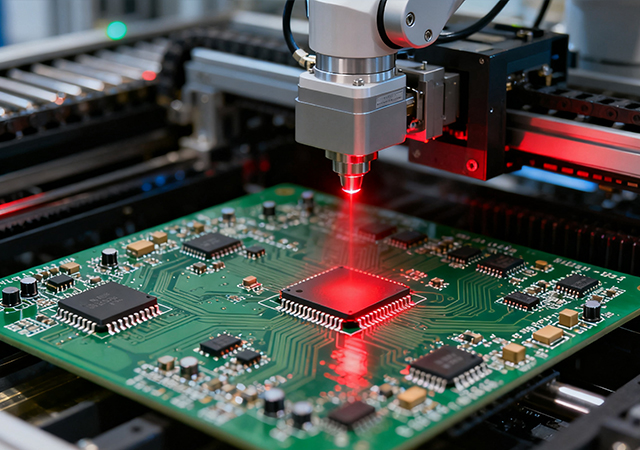

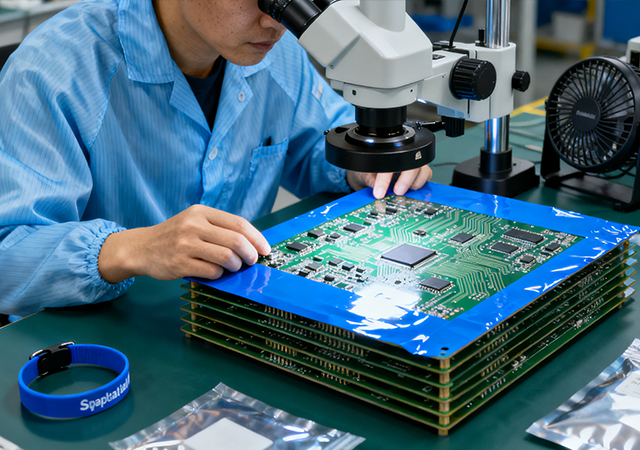

PCB Assembly is undergoing a paradigm shift as manufacturers embrace human-machine collaboration (HMC) to build adaptive production systems that balance precision, flexibility, and scalability. Unlike traditional assembly lines—where humans and machines operate in silos—modern PCB assembly integrates skilled technicians with advanced automation (cobots, AI-driven inspection tools) to address evolving industry challenges: from labor skill gaps to the rise of low-volume, high-mix production. This collaboration transforms PCB assembly from a rigid process into a dynamic ecosystem, where machines handle repetitive, high-precision tasks while humans oversee complex decision-making, troubleshooting, and design refinement. As electronics markets demand faster customization and shorter lead times, HMC-powered PCB assembly has become a competitive differentiator. This article explores the core dimensions of human-machine collaboration in PCB assembly, its role in enabling adaptive manufacturing

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB