-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

Support Through-Hole PCB, Flexible Circuit Board (FPC), HDI, Blind Buried Via, Carbon Film Board, etc. The monthly production capacity can reach 50,000 square meters, TS16949/UL/CE/RoHS/ISO9001 certification, standard configuration Flying probe test,E-test fixture, AOI (Automatic Optical Inspection) and other Visual inspections. [see more]

With a long-term and stable supply chain, we have established 5-10 years of cooperation with the original manufacturers and agents of IC, resistors, capacitors, inductors, connectors, crystal oscillators, display screens, transformers, relays, diodes and other classified devices. Support in terms of billing period and technical after-sales. Our company has established an internal SQE annual audit mechanism to evaluate all suppliers, and the survival of the fittest, so as to continue to ensure the supply capacity and quality capabilities of components. [see more]

Steel sheet thickness: 0.08mm/0.1mm/0.12mm/0.15mm/0.18mm/0.2mm/0.25mm/0.3mm, of which 0.1-0.18mm is the standard thickness, and the Non-standard steel sheet thickness requires additional costs, if the thickness of the steel sheet is not given. The engineer will determine the thickness of the steel sheet according to the component type in the document. For example, if there is a dense foot IC in the document, the thickness should be less than 0.12, and the thickness should be 0.15mm and above if there is no IC.

Stencil opening: If the customer does not provide opening requirements, the resistor/capacitor/diode/transistor will be opened according to the file patch layer 1:1; IC/BGA original width: opening according to industry standards, length: according to 1:1 to make a hole.

MARK point: Generally, if there are MARK points in the file for steel meshes above 42*52, the steel mesh will be half-engraved black with MARK points. If there is no MARK point requirement, we will not process.

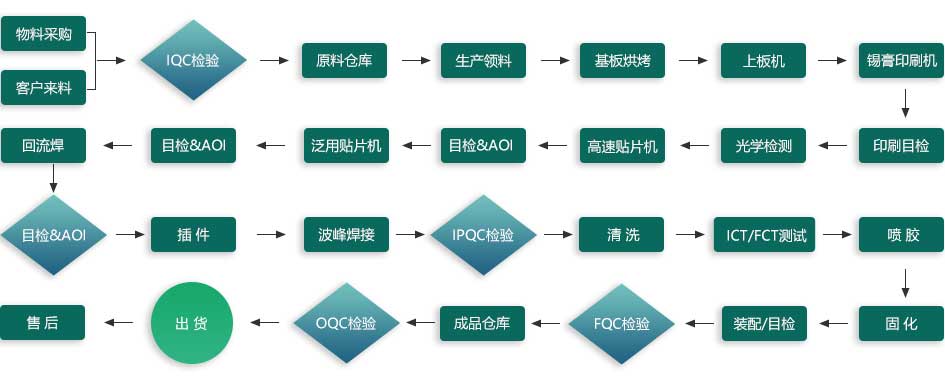

ApolloPCB provides SMT placement processing services for mid-to-high-end customers. The company is equipped with 9 fully automatic high-speed SMT patch production lines, fully-automatic board loading machines, fully-automatic solder paste printers, SPI solder paste thickness detectors, multi-temperature zone reflow soldering, AOI optical inspection equipment, X-Ray inspection machine, baking machine, stencil cleaning machine, etc. The company has passed ISO9001:2015 quality management system, ISO13485 medical device management system, ISO 14001 environmental management system certification, and supports the placement of 01005 components, 0.4mm Pitch BGA, QFN and other precision electronic components.

ApolloPCB provides SMT placement processing services for mid-to-high-end customers. The company is equipped with 9 fully automatic high-speed SMT patch production lines, fully-automatic board loading machines, fully-automatic solder paste printers, SPI solder paste thickness detectors, multi-temperature zone reflow soldering, AOI optical inspection equipment, X-Ray inspection machine, baking machine, stencil cleaning machine, etc. The company has passed ISO9001:2015 quality management system, ISO13485 medical device management system, ISO 14001 environmental management system certification, and supports the placement of 01005 components, 0.4mm Pitch BGA, QFN and other precision electronic components.

It is mainly to detect the voltage/current data of the test points after the PCB circuit board is powered on, and does not involve the test of function keys or input and output.

It is necessary to load the prepared microcontroller (MCU) program into the program IC through a programmer (such as ST-Link, JTAG) to realize the corresponding functional test. For example, after pressing the button, the LED light is on; pressing the two buttons at the same time will restore the factory settings and so on. Of course, whether the test of all functions can be carried out must be based on the premise that the PCB welding is OK and the circuit is connected, otherwise it cannot be realized.

For PCBA boards that have been programmed and passed by FCT, perform long-term and periodic simulation of user input and output to test their durability and welding reliability. Under special circumstances, it is also necessary to expose the PCBA board to a specific temperature and humidity environment.

We support offline programming and online programming. IC types include: eMMC, eMCP, MCU/MPU, EPROM, EEPROM, Serial EPPROM, FLASH, MCP, PLD/CPLD, etc. IC packages include: DIP, SDIP, SOP, SSOP, PLCC, MLF, TSOP, TSSOP, BGA, QFP, etc. IC packaging: Tary, Tube,Tape

The process of DIP can generally be divided into: component forming processing → plug-in → wave soldering → component cutting foot → repair welding (post welding) → washing board → function test

Conformal Coating is a specially formulated coating used to protect circuit boards and related equipment from environmental erosion. Conformal Coating has good resistance to high and low temperature; after curing, it forms a transparent protective film, which has excellent insulation, moisture resistance, leakage resistance, shock resistance, dust resistance, corrosion resistance, aging resistance, corona resistance and other properties. In order to meet the needs of customers' products for applications in harsh environments such as humidity, temperature, and corrosion, our professional Conformal Coating spraying production line includes a fully automatic one-stop mode of spraying equipment, UV detection, and baking.

We configure our production equipment for medium and high-end product quality and small and medium batch orders, so that our technology and manufacturing experience can be better utilized with the cooperation of precision equipment. The SMT patch workshop has complete equipment. In the entire production process, people, equipment, and materials are efficiently connected, and quality and efficiency can be well balanced. Certain special processes and special materials can also be easier to ensure accuracy and yield, such as: 01005, BGA pitch 0.2MM, QFN, CSP, CON and other components

|  |  |

|

|

|

|

|

|

• For potential defects or non-conformance items, use tools such as testing, simulation, data analysis, and QC techniques to analyze and carry out appropriate error-proof design and quality control, and propose preventive measures.

• For defective or non-conformance items that have occurred, the problem solving team will review and approve and revise related technologies, quality standards, or improve the level of technology or design, etc., to confirm whether all products or processes related to the quality system have similar problems and carry out comprehensive prevention And propose solutions.

[People]: From material procurement to product delivery, each link is equipped with quality personnel, including: incoming material inspection IQC, production inspection IPQC, finished product inspection OQC, etc. The production technology and management personnel have more than 5 years of manufacturing experience in the relevant electronics industry, and solve problems in a more timely and effective manner.

[Machine]: In order to meet the high-end and high-end quality requirements of customers, in addition to high-end production equipment, our company is also equipped with sophisticated PCBA testing equipment, including: X-ray, AOI, UV testing platform, FCT equipment, etc. Let each piece stand the test of quality.

[Material]:A procurement team with more than 6 years of experience in electronic component procurement can not only achieve full BOM procurement of orders, but also guarantee the quality of materials to the greatest extent. Especially the cooperation with regular component brand distributors and original factories has greatly improved the advantages of price, delivery, quality, etc., such as Arrow, Mouser, Digi-Key, Litron, etc.

[Material]:A procurement team with more than 6 years of experience in electronic component procurement can not only achieve full BOM procurement of orders, but also guarantee the quality of materials to the greatest extent. Especially the cooperation with regular component brand distributors and original factories has greatly improved the advantages of price, delivery, quality, etc., such as Arrow, Mouser, Digi-Key, Litron, etc.

[System]: Regardless of whether it is material storage, semi-finished products, and finished products storage, the data is stored through the ERP system in accordance with the coding rules and entry standards, so that product quality can be traced. Equipped with FAI first-piece inspection system can greatly reduce the risk of wrong materials and under-materials, and at the same time can improve production efficiency.

After inspection and evaluation by an authoritative institution, Gaotuo’s products, processes and services meet specific requirements such as ISO9001, ISO13485, ISO14001, IPC standards, UL, SGS, RoHs, etc., and relevant certification certificates have been issued, and it has the ability to continuously and stably produce products that meet the requirements of the standards.

We provide PCBA full-process professional services, from the procurement of electronic components to semi-products and finished products, we can accurately meet customer needs, and go all out to realize customer products from plans and drawings to PCBA finished products.

*BOM(Bill of Material):It is called a bill of materials, also called a product structure table, a bill of materials, and so on. Disassemble the raw materials, parts, and assemblies of the product, and record each individual material in the order of the manufacturing process according to the material code, product name, specification, unit usage, location coordinates, loss, etc., and arrange them into a bill of materials. It is BOM. It is mainly used for important documents such as order quotation, material procurement, delivery estimate, production and procurement planning, supporting material picking, tracking logistics, etc. The BOM is not only a technical document, but also a link between the various departments.

*Gerber:A file is a computer software, a collection of file formats for describing circuit boards (circuit layer, solder mask layer, character layer, silk screen layer, stencil layer, etc.) images and drilling and milling data in the circuit board industry. It is a circuit board industry Standard format for image conversion. Mainly used in: opening steel mesh, making patch procedures, PCB quotation, etc.

Others:Pick&Place files, placement diagrams, SMT proofing and placement guide files, test guide files, special process files, etc.

Data analysis: the fastest 2 hours, conventional quotation: 1 day, domestic conventional material purchase: 3-7 days, average foreign material approximately: 15-25 days, conventional PCB manufacturing approximately: 1-3 days, SMT patch: all materials are available The fastest is 1 day.

Shenzhen Apollo Precision Electronic Co.,ltd, with more than twenty years of customer service experience for mid-to-high-end PCBA products, has established a one-stop service that adapts to a wide range of large, medium and small quantities of PCBA products, including: electronic components Procurement, PCB manufacturing, SMT patch, DIP plug-in, three-proof paint coating, packaging, etc.

And it has established cooperative relationships with more than 200 customers in more than 30 countries around the world. Services and products are widely used in industrial control, electric energy, medical equipment, automotive electronics, Internet of Things, AI artificial intelligence, security, electronic communications, finance, and commerce etc.

Industry Control |

|

|

|

| Medical |

|

|

|

| Transportion |

|

|

|

| Telecom/LiFi |  |  |  |

Excellent team, professional service and customer satisfaction are the eternal requirements of APOLLOPCB

|

|

|

|

|

|

|

|

Details determine the pros and cons of an enterprise, and business philosophy determines the quality of services provided. Over the past 21 years, ApolloPCB has not sought the scale of the factory area, but has worked hard on the service and details, from the layout of every small work form to the construction of the enterprise service system, from the 5S standardization and rectification of each workbench to the business operation. The implementation of the concept all embodies the hard work and wisdom of every Apollo person. It is also the reason why more than 300 large and medium-sized enterprises in more than ten fields choose ApolloPCB.

|

|

Conformal Coating |

Office |

QC department | Assembly |

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB