-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

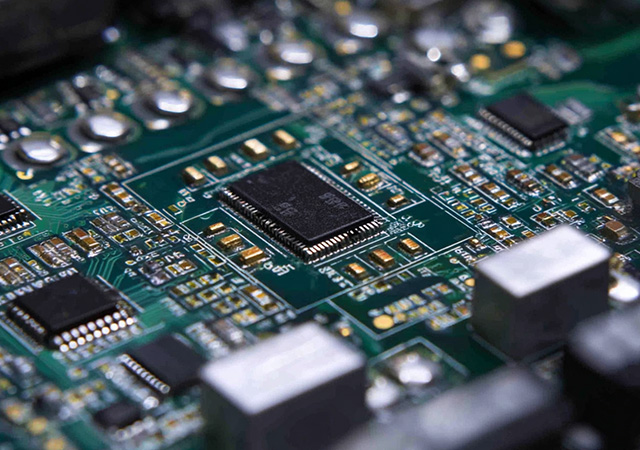

In the ever-shrinking universe of advanced electronics, where devices must pack unprecedented power into palm-sized forms, a revolutionary pairing has emerged: Blind and Buried Vias (BBVs) in Aluminum High-Density Interconnect (HDI) PCBs. This technology represents a quantum leap beyond traditional through-hole vias, enabling engineers to create electronic marvels that blend extreme miniaturization with robust thermal management. Picture a world where smartphones host AI processors in spaces once occupied by simple chips, where medical implants monitor vital signs with nanoscale precision, and where aerospace systems withstand the harshest environments while shrinking in size—all made possible by the intricate dance of BBVs within aluminum HDI structures. This article delves into the technical wonders, manufacturing complexities, and transformative applications of this cutting-edge technology, illuminating how it’s reshaping the future of electronics.

In the bustling universe of modern electronics, where tiny chips pulse with the power of thousands of stars, a quiet revolution is taking place. Aluminum Printed Circuit Boards (PCBs) emerge as the unsung heroes, the master builders tasked with taming the fiery beast of heat that threatens to engulf our technological marvels. Picture a world where every smartphone, every streetlight, every medical device is a delicate balance between incredible power and precise cooling—this is the domain of aluminum PCBs. Unlike their fiberglass counterparts, these boards harness the earth's own aluminum, blending it with cutting-edge materials to create pathways that carry away heat like rivers 疏导洪水,ensuring our devices shine bright without burning out.

In the ever-evolving electronics industry, aluminum PCB manufacturers play a pivotal role in addressing one of the most critical challenges: thermal management. As electronic devices continue to grow in power density while shrinking in size, the demand for efficient heat dissipation solutions has never been higher. Aluminum printed circuit boards (PCBs) have emerged as the go-to solution, and the manufacturers behind these boards are at the forefront of technological innovation, material science, and manufacturing excellence. This article delves into the world of aluminum PCB manufacturers, exploring their technical capabilities, manufacturing processes, industry applications, and the key factors that set them apart in a competitive global market.

In the bustling world of electronic manufacturing, where precision and reliability are non-negotiable, ISO 9001-certified aluminum PCB suppliers stand as beacons of quality. Imagine a sprawling factory bathed in the glow of precision instruments, where every sheet of aluminum undergoes a transformation guided by meticulous processes. These suppliers are the silent guardians of electronic integrity, their facilities humming with the rhythm of standardized excellence. From the moment raw materials enter their gates to the final shipment of finished PCBs, every step is a testament to their commitment to the ISO 9001 framework—a commitment that ripples through global supply chains, powering everything from everyday devices to advanced aerospace systems.

Beneath the glow of Shenzhen's skyscrapers and along the industrial corridors of the Pearl River Delta, a quiet revolution is underway. China's aluminum PCB manufacturers have emerged as the unsung heroes of the global electronics industry, their factories humming with the rhythm of innovation. From the bustling workshops of Guangzhou to the high - tech campuses of Suzhou, these manufacturers have transformed China into the world's leading producer of aluminum printed circuit boards, blending ancient craftsmanship with cutting - edge technology.Imagine a vast factory floor where robotic arms dance over sheets of shimmering aluminum, etching intricate circuits with laser precision. This is the world of Chinese aluminum PCB manufacturers, where every day, thousands of boards are born—each a testament to the country's rise as a manufacturing superpower. These boards will go on to power everything from the LED lights that illuminate city streets to the advanced avionics systems guiding air

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB