-

- PCB TYPE

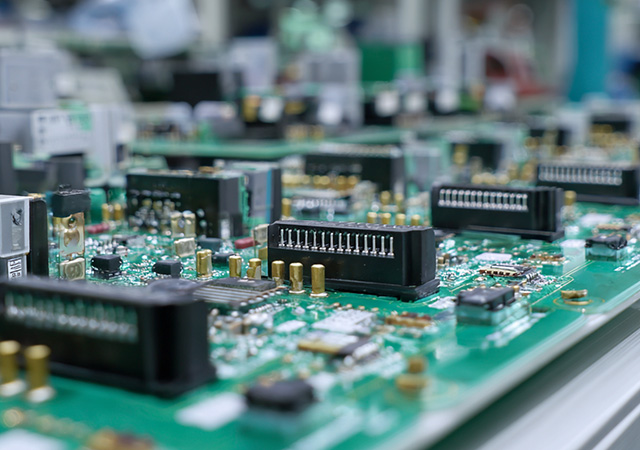

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Introduction: The Pivotal Role of Chinese OEM Aluminum PCB Factories In the global electronics manufacturing landscape, Chinese original equipment manufacturer (OEM) aluminum printed circuit board (Al PCB) factories have established themselves as indispensable partners for businesses seeking customized, high-reliability circuit board solutions. With the electronics industry's relentless pursuit of smaller form factors, higher power densities, and improved thermal management, these factories have emerged as leaders in delivering tailored Al PCB solutions that meet the unique demands of diverse sectors—from automotive and aerospace to consumer electronics and renewable energy. Chinese OEM Al PCB factories distinguish themselves through a unique combination of technical expertise, manufacturing scale, and supply chain efficiency. They serve as critical cogs in the global electronics value chain, enabling product innovation by translating client concepts into manufacturable designs and d

The Rise of China in Low-Cost Aluminum PCB ManufacturingIn the global electronics industry, China has emerged as a dominant force in producing low-cost aluminum-based printed circuit boards (Al PCBs) without compromising technical performance. As demand grows for energy-efficient, thermally robust PCBs across consumer electronics, automotive systems, and industrial applications, Chinese manufacturers have leveraged supply chain integration, manufacturing scale, and technological innovation to offer Al PCB solutions that combine cost-effectiveness with reliability. This article explores the factors driving China’s leadership in low-cost Al PCB production, the engineering strategies behind affordable designs, and the impact of Chinese manufacturing on global electronics supply chains.The rapid expansion of China’s PCB industry over the past two decades has been nothing short of revolutionary. From humble beginnings as a low-cost manufacturing hub, the country now accounts for over 50% of

In the ever-advancing landscape of electronic engineering, aluminum-based printed circuit boards (Al PCBs) have emerged as a transformative solution for applications demanding superior thermal management and mechanical resilience. Departing from traditional FR-4 substrates, Al PCBs harness aluminum’s unique physical properties to address critical challenges in heat dissipation, structural integrity, and electromagnetic compatibility. This article delves into the technical advantages, diverse applications, and engineering considerations of aluminum PCBs, illuminating their role in enabling innovation across automotive, aerospace, power electronics, and beyond.

In the realm of advanced electronics, aluminum-based printed circuit boards (Al PCBs) incorporating blind and buried vias have emerged as a cornerstone of high-performance circuit design. These specialized via technologies address the dual challenges of signal integrity and thermal management in applications ranging from 5G communications to aerospace radar systems. This article delves into the technical synergies, design considerations, and manufacturing complexities of integrating blind and buried vias in Al PCBs, highlighting their role in enabling next-generation electronic systems.

In the ever-evolving realm of radio frequency (RF) technology, the demand for advanced printed circuit boards (PCBs) has reached unprecedented heights. RF applications, spanning from 5G wireless networks to aerospace radar systems, impose rigorous demands on PCB design, particularly in signal integrity, thermal management, and durability. Among the innovative solutions, aluminum-based PCBs (Al PCBs) integrated with blind vias have emerged as a pivotal technology to address these challenges. This article explores the technical intricacies, operational advantages, and practical considerations of incorporating blind vias into Al PCBs for RF applications, highlighting how this combination revolutionizes performance and reliability in high-frequency environments.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB