-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

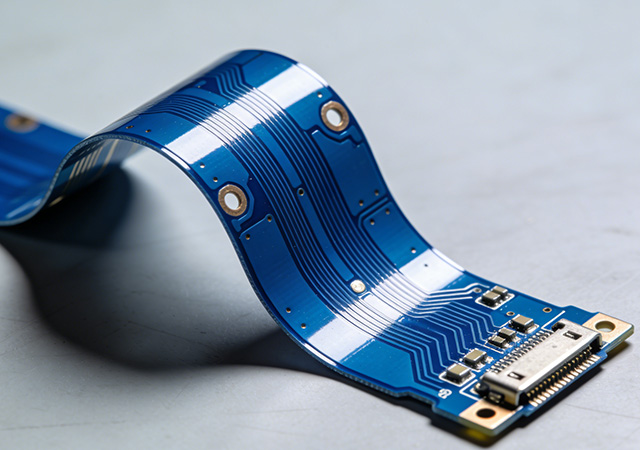

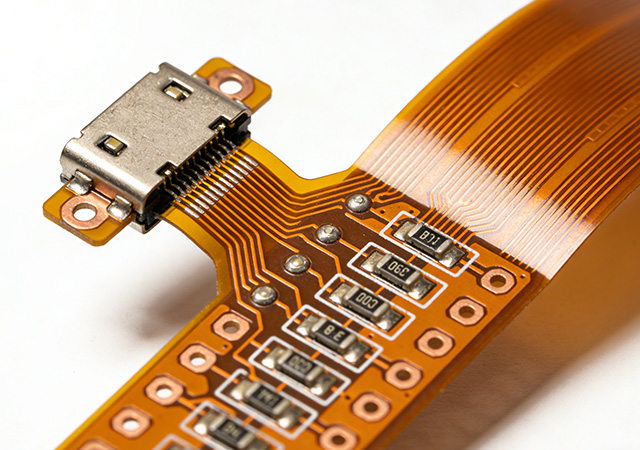

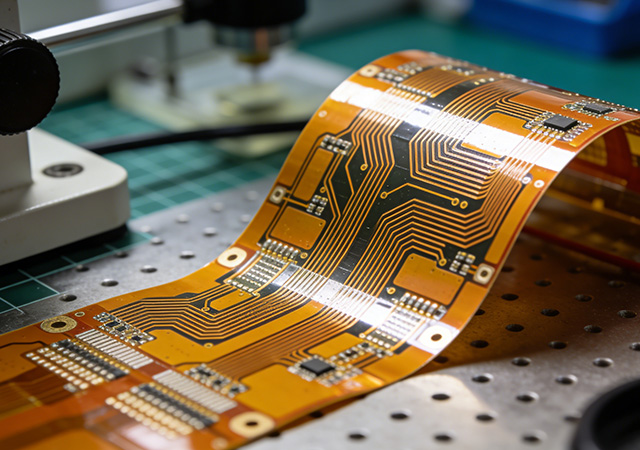

In the globalized electronics industry, flexible printed circuits (FPCs) serve as core components across consumer electronics, industrial automation, new energy vehicles, and medical devices. A professional FPC manufacturer stands out through robust global compliance capabilities and seamless cross-industry technology integration, enabling it to navigate diverse market regulations and meet the varied technical demands of different sectors. Unlike regional or niche FPC suppliers, leading FPC manufacturers prioritize global regulatory alignment and cross-domain technical innovation, providing reliable, market-accessible solutions for clients worldwide. For electronics brands pursuing global market expansion and product diversification, partnering with an FPC manufacturer with strong compliance and integration capabilities is a strategic necessity.

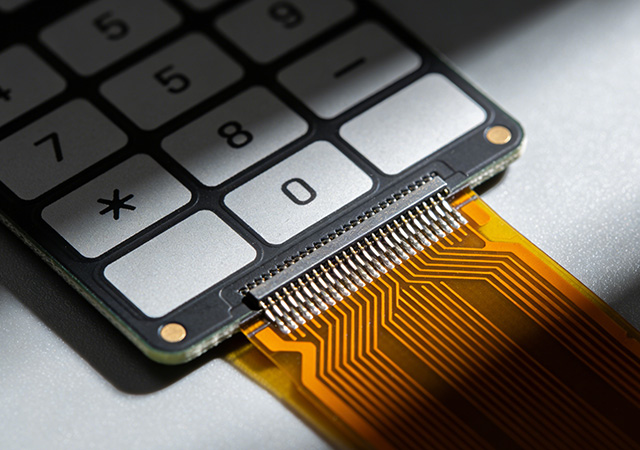

Keypads serve as the vital human-machine interface (HMI) across industrial control systems, automotive dashboards, medical devices, and consumer electronics, requiring flexible printed circuits (FPCs) that combine consistent performance, mechanical resilience, and seamless integration. A professional KeyPads FPC Manufacturer distinguishes itself through end-to-end manufacturing expertise and scenario-driven reliability engineering, going beyond basic component production to deliver FPC solutions tailored to the unique operating demands of diverse keypad applications. Unlike generic FPC producers, specialized KeyPads FPC Manufacturers deeply understand the mechanical and environmental stresses on keypad circuits, ensuring their products withstand repeated usage cycles and harsh conditions. For brands developing high-reliability keypads, partnering with a reputable KeyPads FPC Manufacturer is essential to safeguarding product performance and end-user trust.

In the era of diversified electronic products, keypads—as critical human-machine interaction (HMI) components—are increasingly required to adapt to unique form factors, functional demands, and operating environments. A professional Custom Keypad FPC Design Service stands out as a key enabler for brands seeking differentiated keypad solutions, bridging the gap between conceptual design and practical implementation. Unlike standardized FPC offerings, this tailored service focuses on understanding client-specific requirements, integrating application-driven design strategies, and optimizing flexible printed circuits (FPCs) for keypad performance, compatibility, and user experience. For enterprises developing specialized keypads for industrial control, automotive, medical, or consumer electronics, leveraging a reliable Custom Keypad FPC Design Service is essential to translating innovation into market-competitive products.

Keypads serve as critical human-machine interfaces across industrial control panels, consumer electronics, automotive dashboards, and medical devices, demanding flexible printed circuits (FPCs) that can withstand millions of按压 cycles while maintaining reliable signal transmission. A professional Durable Keypad FPC Manufacturer specializes in engineering FPCs tailored for the unique mechanical stress and environmental challenges of keypad applications. Unlike generic FPC manufacturers, these specialized providers focus on按压 durability, wear resistance, and consistent tactile feedback, ensuring FPCs remain functional even in high-frequency usage and harsh operating environments. For brands developing long-lasting, high-reliability keypads, partnering with a reputable Durable Keypad FPC Manufacturer is essential to delivering products that meet end-users’ expectations for longevity and performance.

In the fast-evolving global electronics industry, the performance and versatility of flexible printed circuits (FPCs) have become decisive factors in product innovation. A professional FPC manufacturer distinguishes itself through cutting-edge material innovation and tailored engineering capabilities, going beyond standardized production to deliver high-performance, application-specific FPC solutions. Unlike generic component suppliers, leading FPC manufacturers prioritize R&D in advanced materials and precision engineering, enabling them to address the unique challenges of emerging electronic applications—from wearable devices to industrial IoT sensors. For electronics brands striving to gain a competitive edge, partnering with an FPC manufacturer that excels in material innovation and customization is essential to unlocking product potential and meeting evolving market demands.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB