-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

As high brightness (HB) LED lighting gains traction in high-demand scenarios—from stadium illumination, high-bay industrial lighting to automotive high-beam headlights and stage lighting—the role of a professional High Brightness LED FPC Supplier has become indispensable. Specializing in flexible printed circuits (FPCs) engineered for high-power, high-lumen LED systems, these suppliers bridge the gap between HB LED’s luminous performance requirements and the technical challenges of power handling, heat dissipation, and light uniformity. Unlike generic LED FPC suppliers, a High Brightness LED FPC Supplier focuses on integrating high-current compatibility, thermal management, and precision circuit design to ensure FPCs can support HB LEDs’ full luminous potential while maintaining long-term reliability. For LED lighting brands aiming to compete in high-brightness segments, partnering with a reputable High Brightness LED FPC Supplier is critical to delivering high-performance, market-lead

As LED lighting penetrates diverse scenarios—from outdoor architectural lighting, automotive exterior lighting to marine and industrial wet-area illumination—the demand for reliable waterproof flexible printed circuits (FPCs) has soared. A professional Waterproof LED FPC Manufacturer specializes in designing and producing FPCs tailored for LED applications with advanced waterproof capabilities, bridging the gap between LED’s high-efficiency lighting needs and the harsh environmental challenges of wet or outdoor use. Unlike generic FPC manufacturers, these specialized providers focus on integrating waterproof technologies with LED-specific performance requirements (e.g., heat dissipation, current stability), ensuring FPCs can withstand moisture, dust, corrosion, and temperature fluctuations while optimizing LED light efficiency. For LED lighting brands aiming to expand into high-value waterproof lighting segments, partnering with a reputable Waterproof LED FPC Manufacturer is critical t

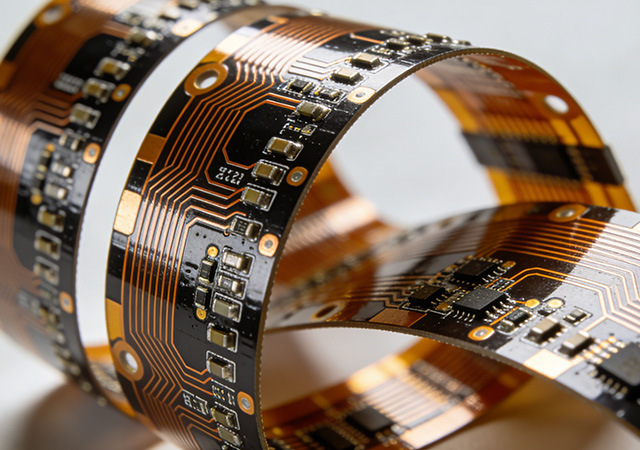

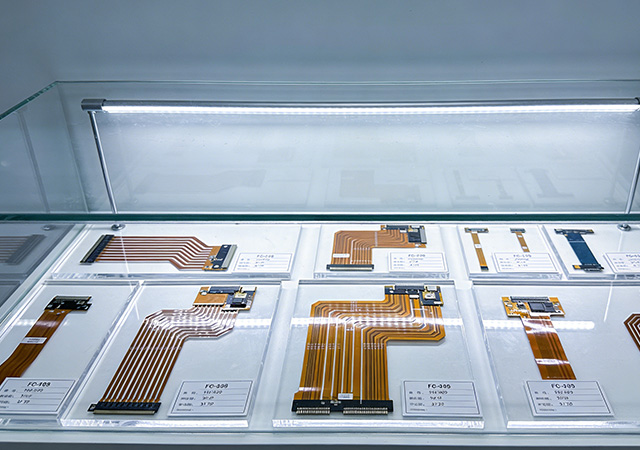

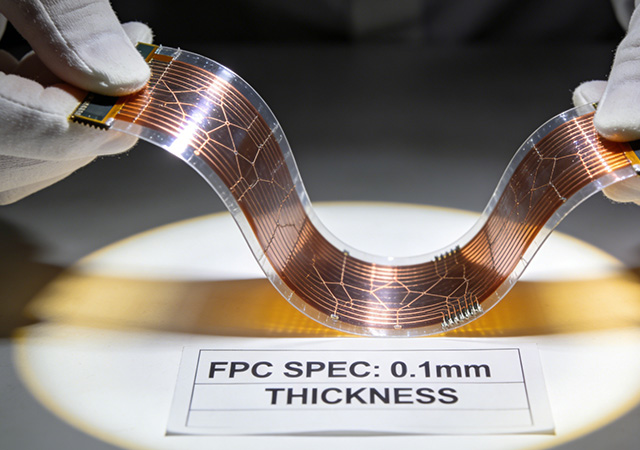

As the global electronics industry evolves toward miniaturization, intelligence, and flexibility, a professional FPC manufacturer has emerged as a foundational pillar of the electronics ecosystem. Unlike niche FPC suppliers focused on single industries, top FPC manufacturers distinguish themselves through exceptional cross-industry adaptability and integrated technological capabilities, tailoring flexible printed circuit (FPC) solutions to the unique demands of industrial automation, medical devices, automotive electronics, and consumer gadgets. These manufacturers are not just component producers—they are strategic partners that bridge material science, process engineering, and industry-specific requirements to deliver reliable, high-performance FPCs. For enterprises across diverse sectors seeking to innovate electronic products, partnering with a versatile FPC manufacturer is critical to unlocking design flexibility, enhancing product reliability, and gaining a competitive edge in gl

As smartphones continue to evolve with advanced features such as 5G connectivity, AI computing, high-resolution imaging, and fast charging, a professional smartphone FPC manufacturer has become a critical catalyst for translating these technological advancements into practical, user-centric devices. Specializing in flexible printed circuits (FPCs) tailored to the unique functional and design demands of smartphones, these manufacturers are not just component suppliers—they are technology partners that proactively iterate FPC solutions to match the rapid pace of mobile innovation. Unlike general FPC manufacturers, a smartphone-focused FPC manufacturer deeply understands the intricate balance between functional integration, power efficiency, and form factor optimization required by modern smartphones. For mobile brands striving to maintain competitiveness in a fast-changing market, partnering with a capable smartphone FPC manufacturer is essential to accelerating product development and d

As smartphone design evolves beyond traditional rigid forms toward foldable, rollable, and slider configurations, a Flexible Smartphone FPC Manufacturer has become a core enabler of this morphological innovation. Specializing in flexible printed circuits (FPCs) engineered for the dynamic operating demands of modern smartphones, these manufacturers go beyond basic flexibility—they tailor solutions to balance mechanical adaptability, signal stability, and long-term durability. Unlike generic FPC manufacturers, a Flexible Smartphone FPC Manufacturer deeply understands the unique stressors of flexible mobile devices (e.g., repeated folding, dynamic component movement) and the industry’s pursuit of versatile user experiences. For smartphone brands aiming to differentiate in the competitive market through innovative form factors, partnering with a professional Flexible Smartphone FPC Manufacturer is a pivotal step in turning bold design concepts into reliable, market-ready products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB