-

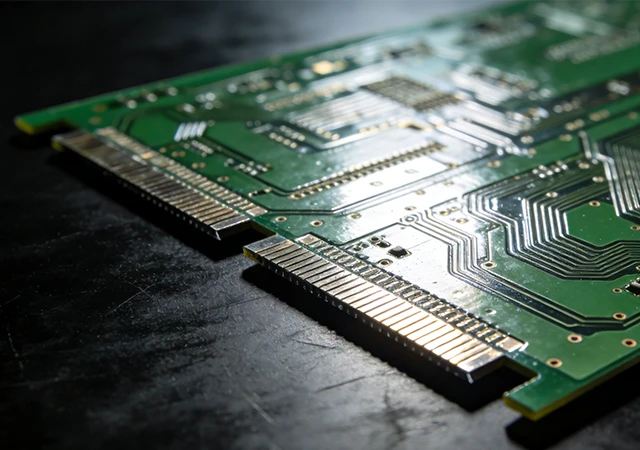

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Looking for a reliable PCB manufacturer? Explore our guide on flex vs fr4 pcb, American pcb manufacturer comparisons, and professional flex pcb assembly services.

Compare pcb assembly & manufacturing costs. Learn about flexible printed circuits, pcb board manufacturing process, and how to find a low-cost pcb assembler.

Compare pcb assembly & manufacturing costs. Learn about flexible printed circuits, pcb board manufacturing process, and how to find a low-cost pcb assembler.

Expert manufacturing pcb services from ApolloPCB. Specialized in prototype pcb manufacturing, blind & buried vias, and back drilling. ISO certified China pcb factory.

Looking for a reliable PCB manufacturer in China? ApolloPCB provides high-quality, ISO & UL certified PCB fabrication and assembly. 20+ years of expertise in industrial & medical electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB