-

- PCB TYPE

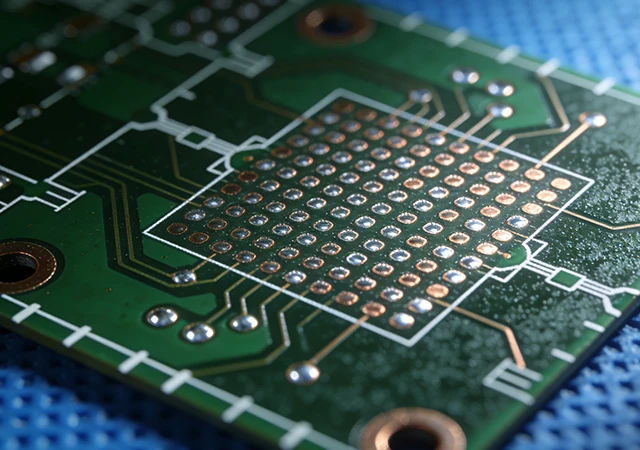

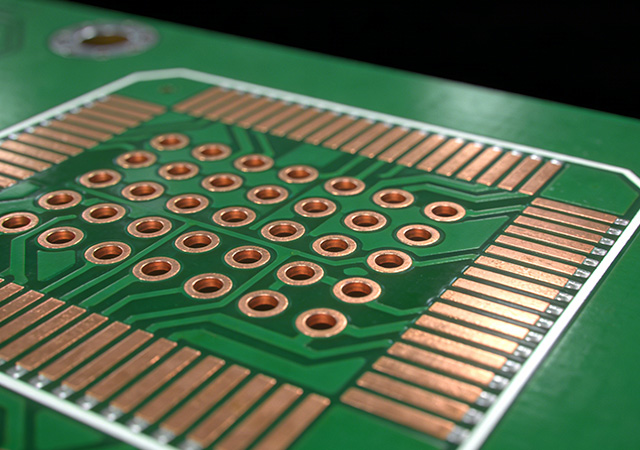

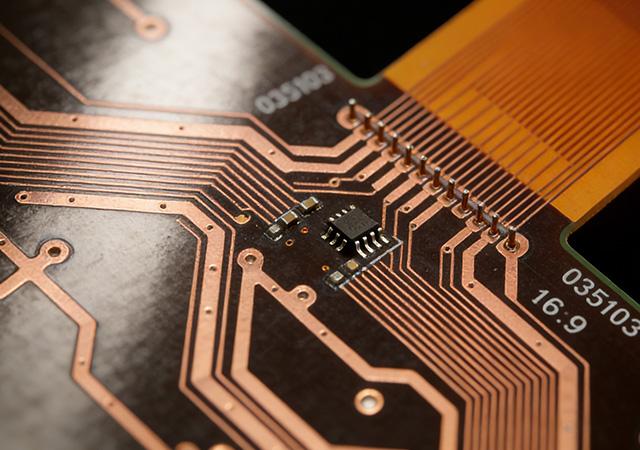

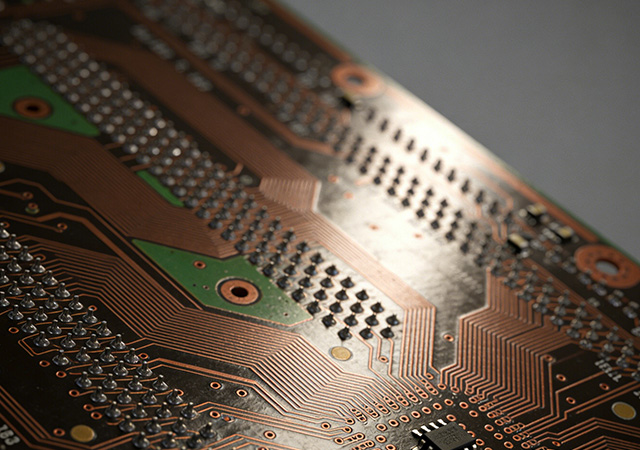

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

ApolloPCB is a leading FR4 PCB manufacturer since 2002. Specializing in High Tg FR4 PCB, multi-layer rigid boards, and complex stackups. ISO & UL certified. Get a 12h quote!

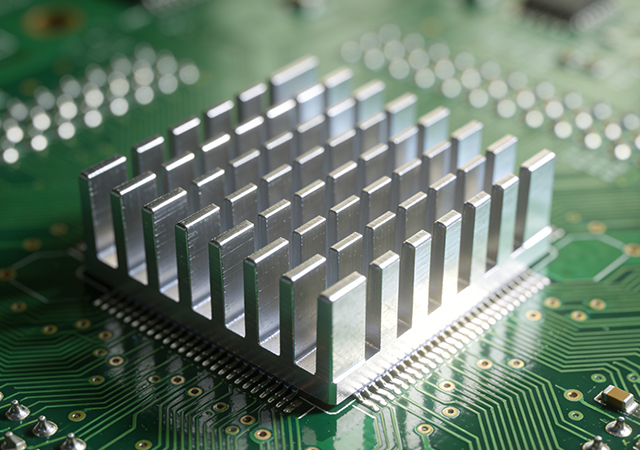

Leading aluminum PCB manufacturer since 2002. We provide single-layer & multi-layer aluminum PCB boards with thermal conductivity up to 9.0 W/m.K. Get a free DFM quote!

Explore what CEM3 PCB is, its Composite Epoxy Material-3 properties, performance advantages, comparing with FR-4, manufacturing insights, key applications, and how to choose a reliable CEM-3 PCB manufacturer for your project.

From FR4 PCB prototypes to stable volume production—clear FR4 PCB material specification, DFM support, and consistent quality. Request a fast quote.

Choose a reliable FR4 PCB manufacturer for prototypes and volume. Learn HIGH TG FR4 PCB options, FR4 PCB material type, thermal conductivity, and temperature rating.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB