-

- PCB TYPE

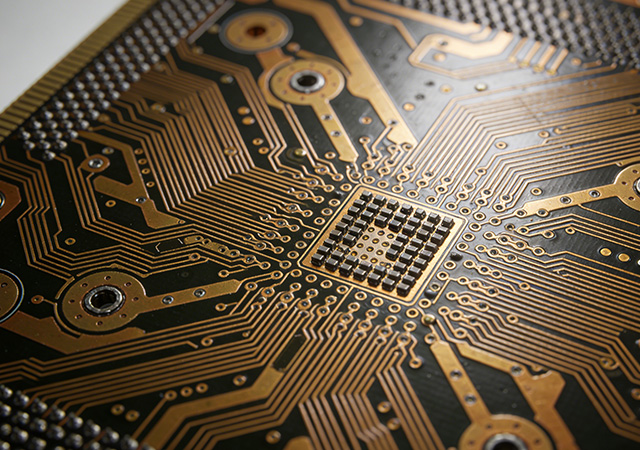

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

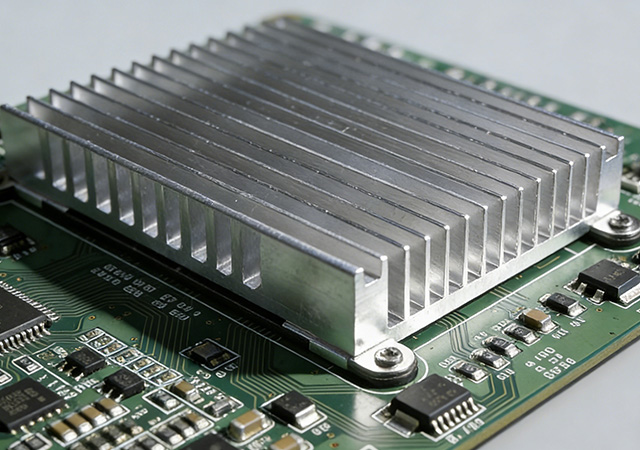

In the rapidly evolving world of high-power electronics, managing heat is the difference between a product’s success and its catastrophic failure. As a leading metal core pcb manufacturer, we have seen the industry shift from traditional substrates to high-performance metal core pcb (mcpcb) solutions.

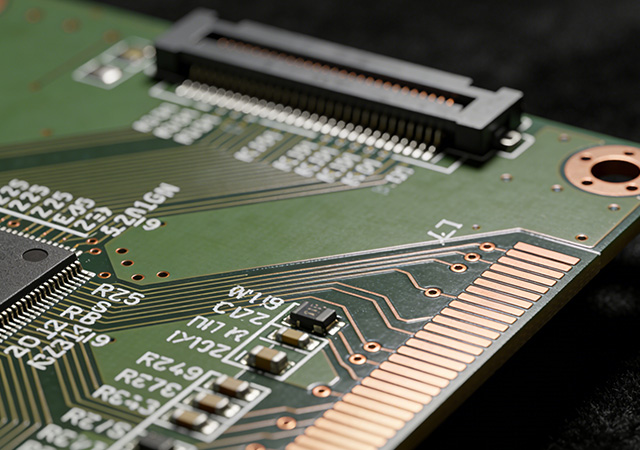

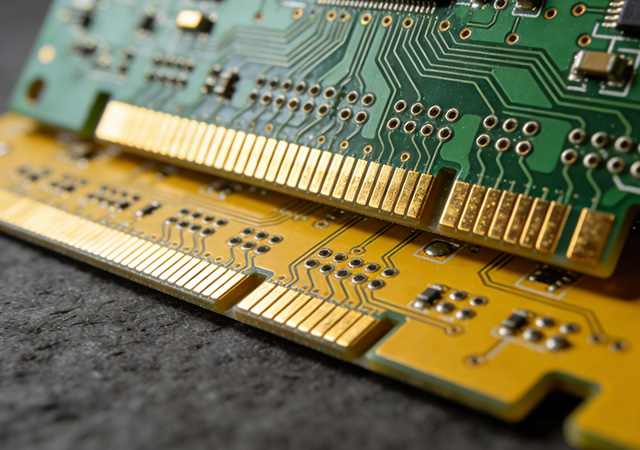

Need a reliable FR4 PCB manufacturer? Fast prototypes to stable volume builds with low CTE FR4, precision machining, and DFM support. Get a fast quote.

Need a reliable FR4 PCB manufacturer? From fast prototypes to mass production, ApolloPCB delivers stable fr4 pcb material options, tight QC, and advanced vias.

Work with a reliable aluminum pcb manufacturer for LED lighting and power. Learn MCPCB structure, automotive PCB use cases, and material options like Ventec, Wazam, and HA80.

From 8 to 13 March 2026, Light + Building will once again open its doors in Frankfurt am Main. The international showcase for innovation will be held under the motto “Be Electrified – Electrifying Places. Illuminating Spaces.”, shining a spotlight on its two core areas: lighting and building services technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB