-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

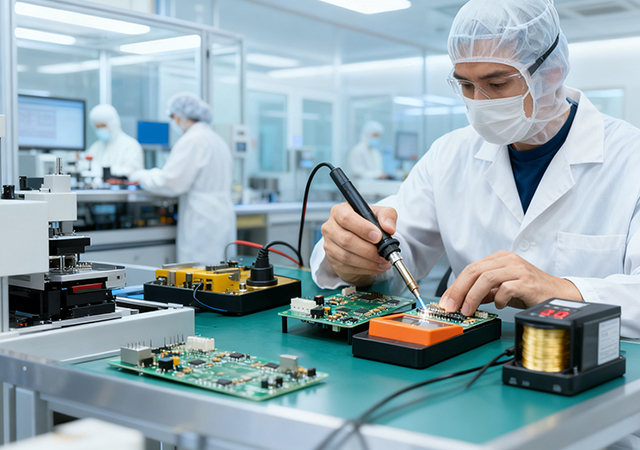

Precision Electromechanical Assembly is a specialized discipline focused on integrating mechanical components, electrical circuits, and micro-systems with sub-micron to micron-level tolerance—catering to applications where even the smallest misalignment can compromise performance or safety. Unlike standard industrial electromechanical assembly, which prioritizes durability for harsh environments, this field demands ultra-fine precision in component placement, alignment, and functional synergy. It underpins the functionality of high-tech systems, from semiconductor lithography machines to medical diagnostic equipment and aerospace guidance systems. As industries push toward miniaturization and high-performance computing, precision electromechanical assembly has become a bottleneck technology, enabling innovations that rely on seamless interaction between mechanical motion and electronic control. This article explores its defining characteristics, core processes, niche applications, and

Industrial Electromechanical Assembly is the critical process of integrating mechanical components, electrical systems, and control logic to build robust, functional industrial equipment—from factory automation robots to power generation turbines. Unlike consumer electronics assembly, which prioritizes miniaturization, this discipline focuses on system-level synergy: ensuring mechanical structures (gears, motors) and electrical components (sensors, wiring harnesses) work in harmony under harsh industrial conditions (extreme temperatures, vibration, chemical exposure). As global manufacturing shifts toward smart factories and industrial IoT (IIoT), electromechanical assembly has evolved beyond basic integration to become a cornerstone of operational efficiency and reliability. This article explores its core characteristics, key processes, industry-specific applications, and emerging trends shaping its future.

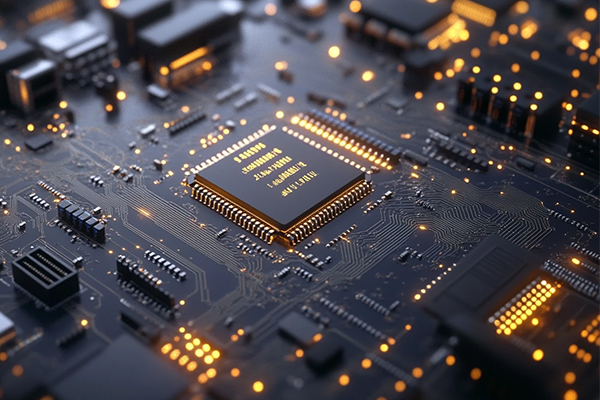

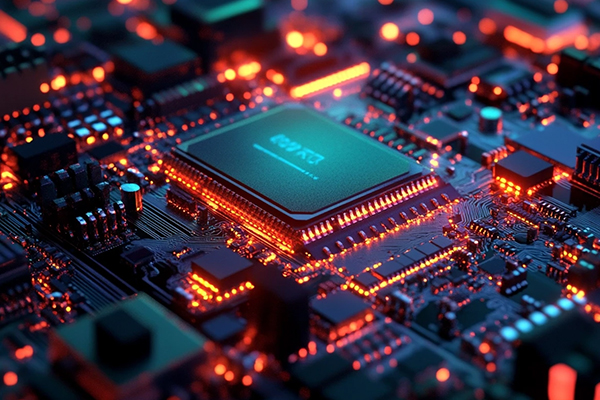

PCB Assembly is undergoing a profound transformation driven by two powerful forces: the convergence of emerging technologies and the global push for sustainability. No longer just a manufacturing step, it has become a nexus where digital innovation, material science, and environmental responsibility intersect to create more efficient, resilient, and eco-friendly electronic systems. From AI-powered process optimization to biodegradable materials, these advancements are redefining what PCB assembly can achieve—supporting the next wave of electronics from green energy devices to smart infrastructure. This article explores how tech convergence is enhancing precision and efficiency in PCB assembly, the sustainable practices revolutionizing the field, and their collective impact on key industries.

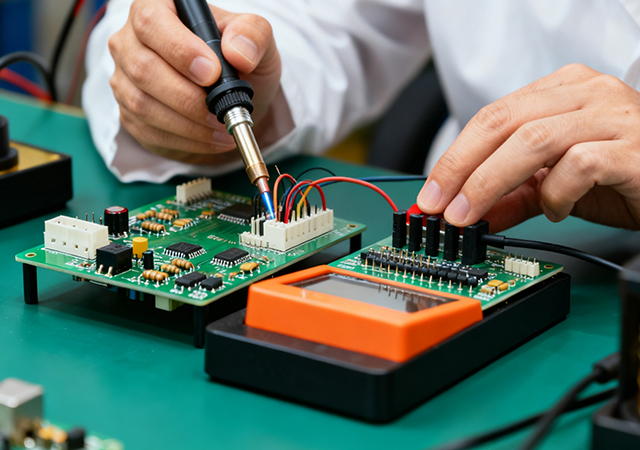

Quick Turn PCB Assembly has become a linchpin of agile electronics development, enabling businesses to accelerate product iterations, test market hypotheses faster, and respond to evolving customer demands with unprecedented speed. Unlike traditional long-lead assembly, which locks companies into rigid production timelines, quick turn services compress the design-to-assembly cycle—typically delivering prototypes or low-to-medium volume runs in days, not weeks. This agility is transformative for industries where innovation pace dictates competitive advantage, from consumer tech startups to industrial IoT developers. This article explores the market drivers behind quick turn adoption, the technical and operational pillars that enable its success, and how it empowers businesses to stay ahead in dynamic electronics landscapes.

Urgent Quick Turn PCB Assembly represents a specialized subset of fast-track manufacturing, designed to address time-sensitive crises and unplanned demands that cannot wait for standard production timelines. Unlike scheduled quick-turn services, urgent assembly prioritizes immediate resource mobilization—often for scenarios where delays could lead to safety risks, significant financial losses, or mission failure. From emergency medical equipment repairs during public health crises to last-minute fixes for aerospace mission components, this service acts as a critical safety net for industries where “time is mission-critical.” This article explores the unique response frameworks, risk-mitigation strategies, targeted use cases, and operational agility that define urgent quick turn PCB assembly.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB