-

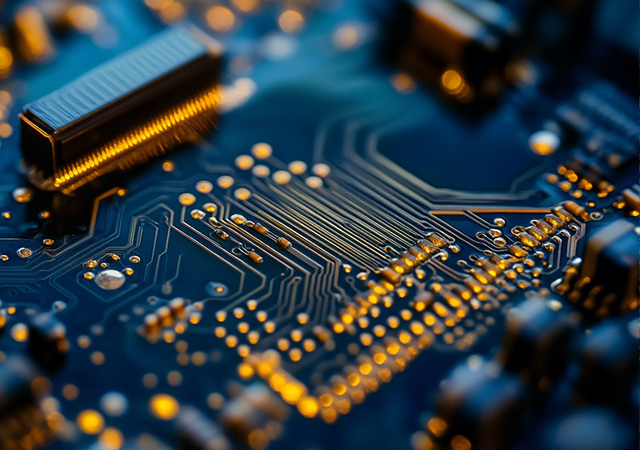

- PCB TYPE

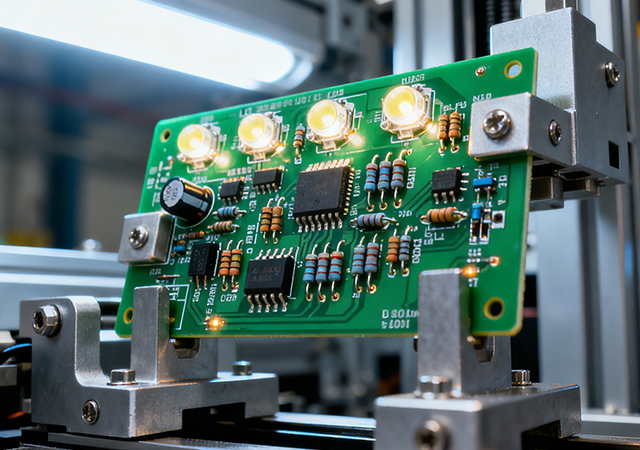

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

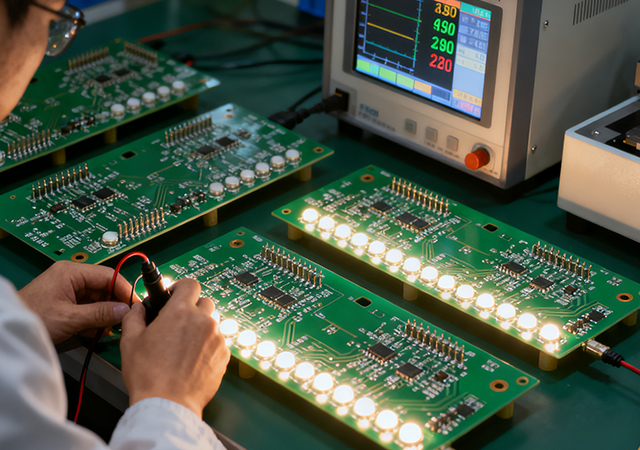

Discover the benefits of LED lighting PCB assembly, including energy efficiency, longevity, and customization. Uncover insights into the PCB assembly process and professional services.

Discover how energy-efficient LED PCB assembly reduces power consumption and enhances performance in electronics, offering sustainable solutions for a greener future.

Discover the benefits of high brightness LED PCB assembly in modern lighting solutions. Learn about energy efficiency, durability, and versatile applications.

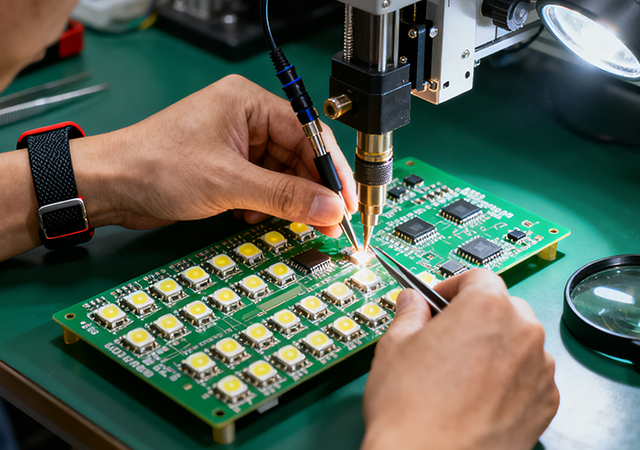

Explore the essential steps of the PCB assembly process, from design to testing, and discover how PCB assembly services can boost efficiency in electronic manufacturing.

Explore the essentials of SMT assembly in electronics manufacturing. Discover how Surface Mount Technology enhances PCB efficiency and device compactness.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB