-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

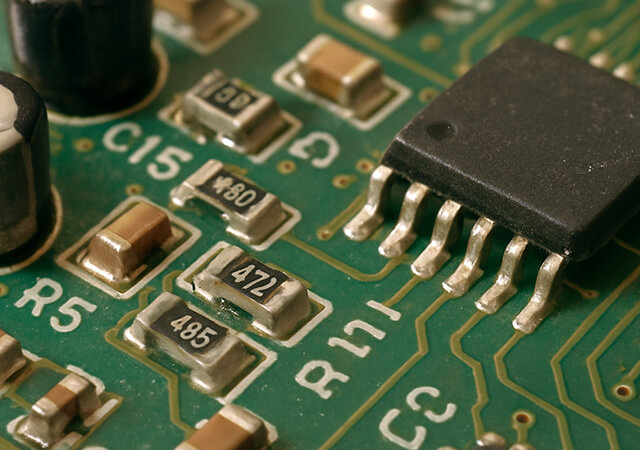

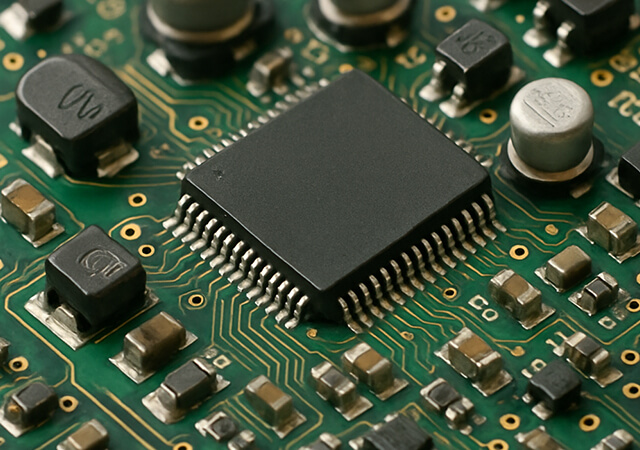

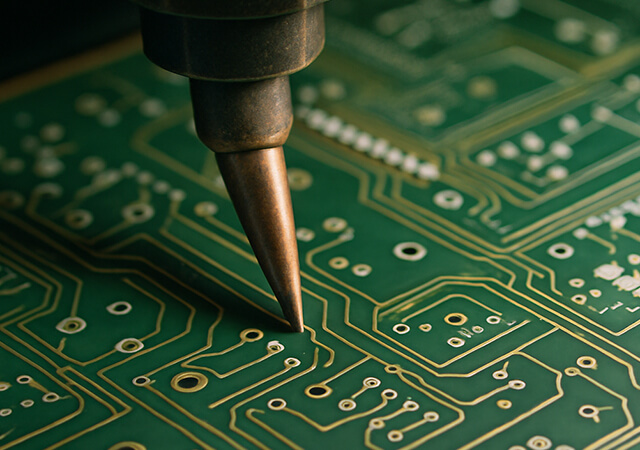

Discover the essential PCB assembly process from design to final product. Learn about PCB design, manufacturing, and assembly techniques for reliable electronics.

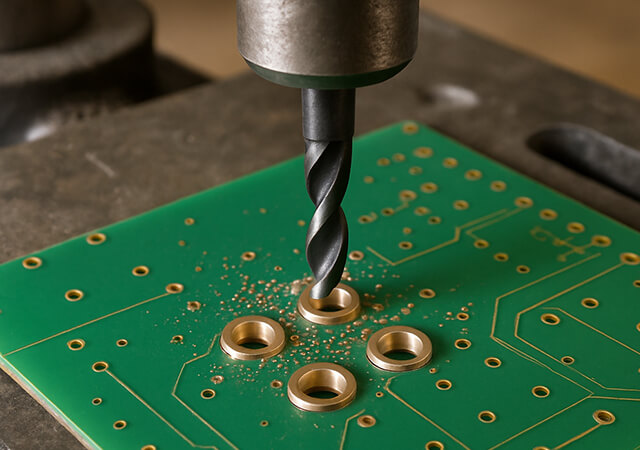

Learn about the crucial role of counterbore holes in PCB assembly for secure fastening and space optimization in electronic designs. Improve your PCB design today!

Explore the significance of tapped counterbore in PCB assembly, enhancing component security, space efficiency, and durability, vital for reliable PCB manufacturing.

Explore the precision of 3mm counterbore PCB assembly work, enhancing mechanical stability and space efficiency in modern electronics.

Discover the intricate PCB assembly process, from pcb design to pcb manufacturing, crucial for creating reliable electronic devices. Explore the steps involved!

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB