-

- PCB TYPE

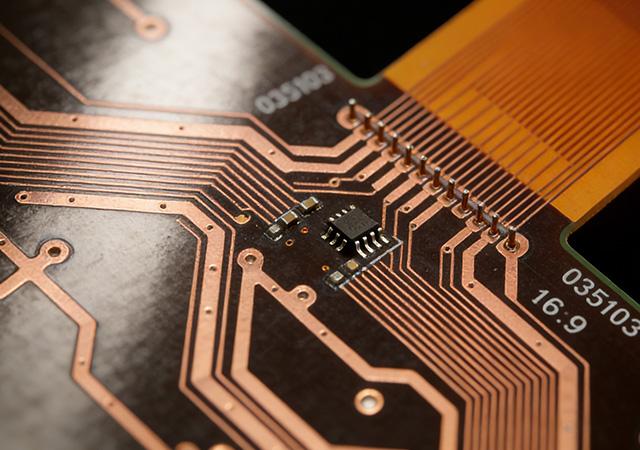

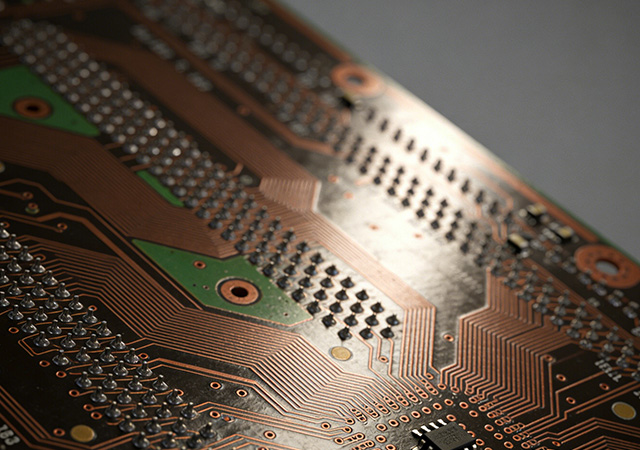

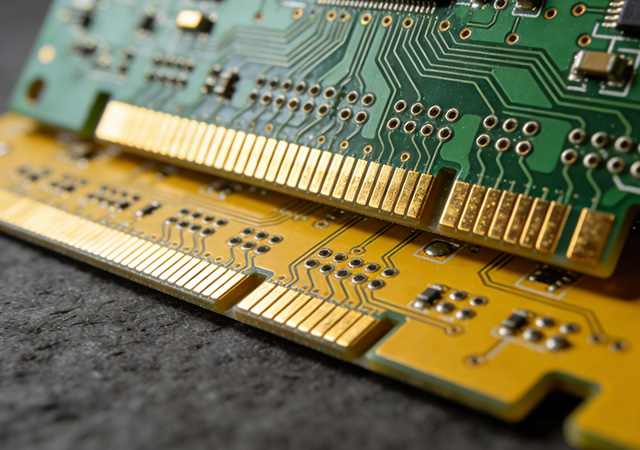

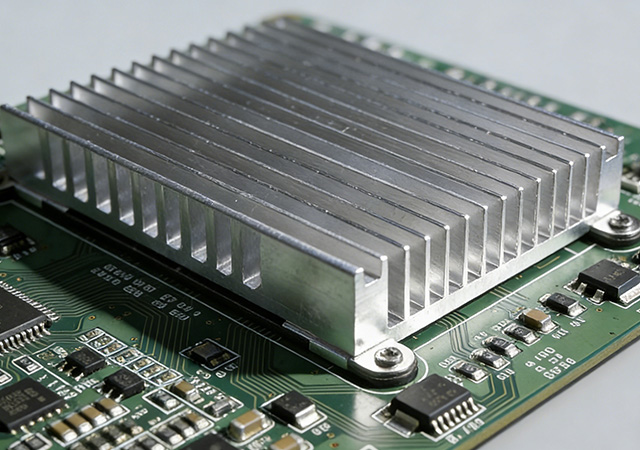

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

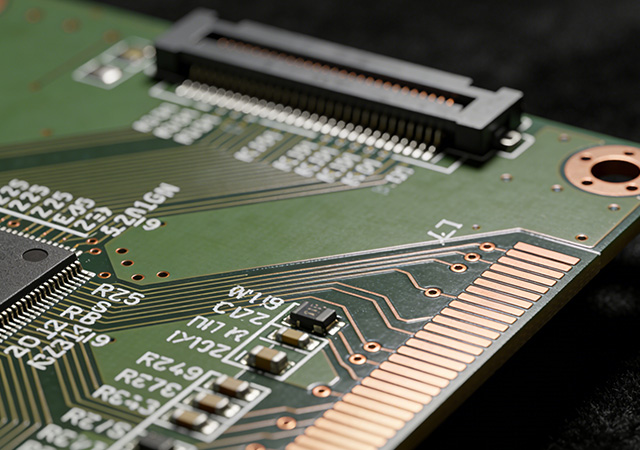

From FR4 PCB prototypes to stable volume production—clear FR4 PCB material specification, DFM support, and consistent quality. Request a fast quote.

Choose a reliable FR4 PCB manufacturer for prototypes and volume. Learn HIGH TG FR4 PCB options, FR4 PCB material type, thermal conductivity, and temperature rating.

Need a reliable FR4 PCB manufacturer? Fast prototypes to stable volume builds with low CTE FR4, precision machining, and DFM support. Get a fast quote.

Need a reliable FR4 PCB manufacturer? From fast prototypes to mass production, ApolloPCB delivers stable fr4 pcb material options, tight QC, and advanced vias.

Work with a reliable aluminum pcb manufacturer for LED lighting and power. Learn MCPCB structure, automotive PCB use cases, and material options like Ventec, Wazam, and HA80.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB