-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

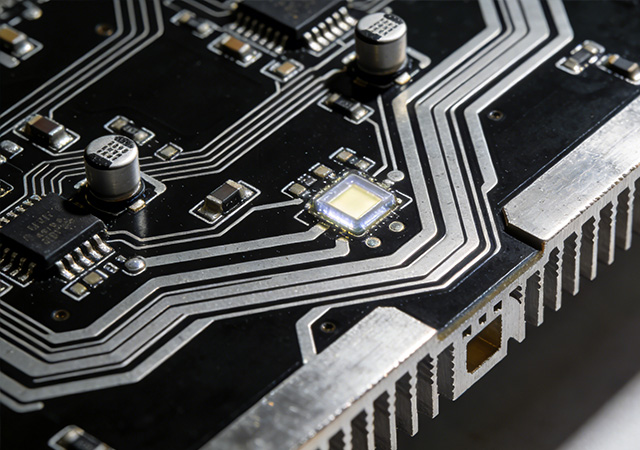

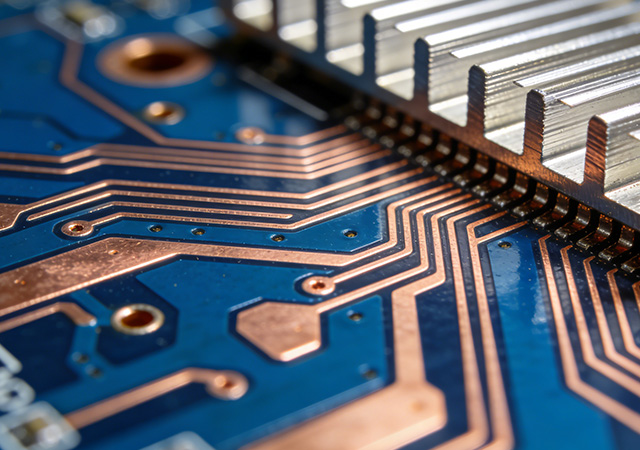

In the rapidly evolving world of electronics, efficient thermal management is crucial for ensuring the longevity and reliability of devices. Traditional PCBs, such as those made from FR-4, often struggle with heat dissipation in high-power applications. This is where metal core PCBs (MCPCBs) come into play, offering superior heat dissipation, mechanical strength, and durability. This article explores the key benefits, applications, and considerations associated with metal core PCB technology, including its use in industries like automotive electronics and high-power systems.

In modern electronics, thermal management has become a crucial aspect of device design, especially as the demand for compact and high-performance systems grows. Traditional PCBs made of FR-4 materials struggle to manage heat effectively, especially in high-power applications. This is where metal core PCBs (MCPCBs) excel, providing superior heat dissipation, improved reliability, and mechanical strength. In this article, we explore the key advantages of metal core PCB technology and its diverse applications in industries like LED lighting, automotive electronics, and more.

In the world of modern electronics, thermal management has become a paramount design consideration — especially as power densities rise and devices become more compact. Traditional PCB materials such as FR-4 struggle to dissipate heat efficiently in high-power environments, which can compromise performance and shorten product life.

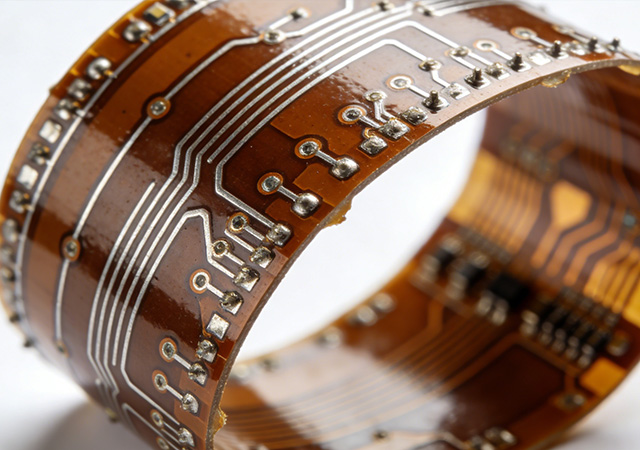

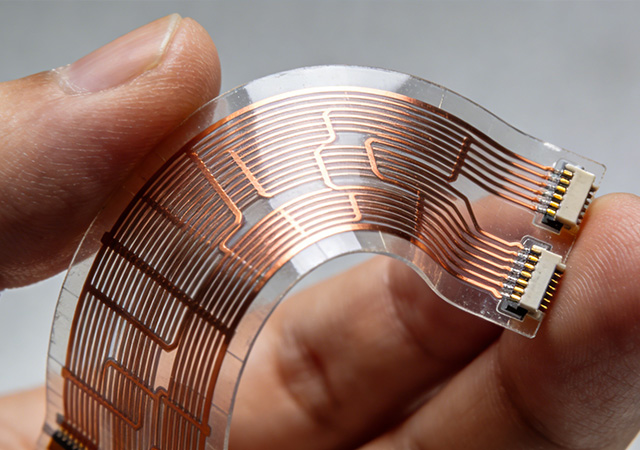

In the age of electronic innovation where adaptability, miniaturization, and integration are paramount, flexible circuit has emerged as a transformative core component, redefining the possibilities of electronic product design. Unlike rigid printed circuit boards that impose structural limitations, flexible circuit leverages bendable, lightweight, and high-reliability materials to enable electronic devices to conform to diverse form factors and operating environments. From consumer tech gadgets to industrial sensors and medical devices, flexible circuit serves as the foundational connection hub, facilitating seamless signal transmission and component integration. As industries strive to develop more ergonomic, portable, and intelligent products, the unique capabilities of flexible circuit have made it an indispensable driver of modern electronic design evolution.

In the era of electronic miniaturization and intelligence, Flexible Circuit Assembly has evolved from a niche component process to a foundational technology that powers diverse electronic products. This assembly process leverages the inherent flexibility and compactness of flexible circuits, integrating electronic components into adaptive, space-efficient designs that overcome the limitations of rigid circuit assemblies. From everyday consumer gadgets to industrial automation systems and new energy equipment, Flexible Circuit Assembly enables seamless component integration, reliable signal transmission, and optimized product form factors. As industries pursue lighter, thinner, and more functional electronic devices, the versatility and adaptability of Flexible Circuit Assembly have made it an indispensable driver of modern electronic innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB