-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

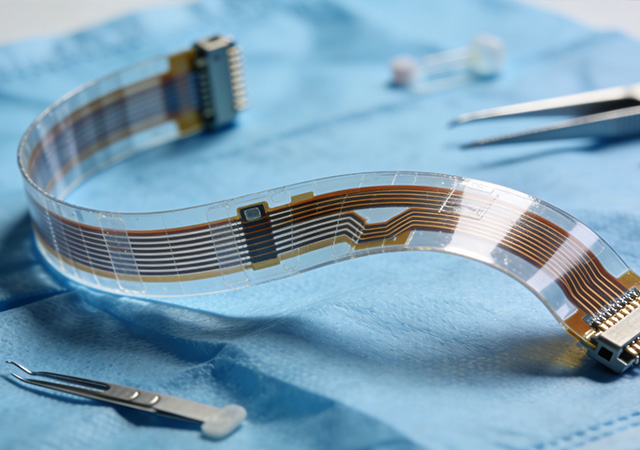

In the rapidly advancing landscape of healthcare technology, the demand for miniaturized, reliable, and biocompatible electronic components has elevated Medical Grade Flexible Circuit Assembly to a pivotal position. Unlike standard flexible circuit assembly, Medical Grade Flexible Circuit Assembly is engineered to meet the most stringent regulatory and performance requirements, as it directly impacts patient safety and treatment outcomes. This specialized assembly process integrates flexible circuit technology with medical-specific design principles, enabling the development of innovative devices ranging from implantable bioelectronics to minimally invasive surgical tools. As healthcare evolves toward personalized and precise medicine, Medical Grade Flexible Circuit Assembly has become an indispensable enabler, ensuring that life-critical devices deliver consistent performance in the complex and sensitive environment of the human body.

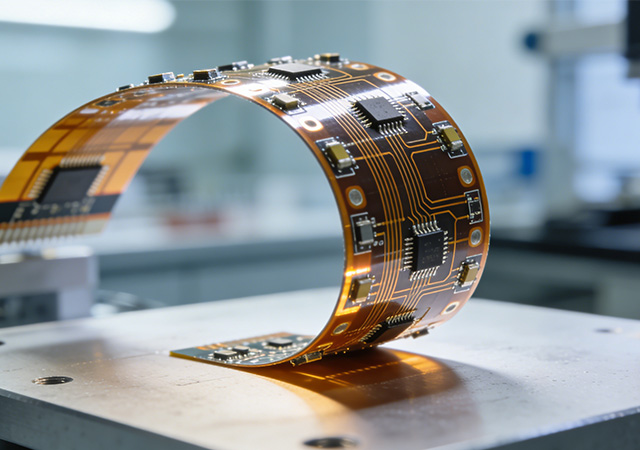

In the realm of advanced electronics, where performance margins are narrow and operational reliability is non-negotiable, High Precision Flexible Circuit Assembly has emerged as a foundational technology. This specialized assembly process combines the inherent flexibility of flexible circuits with ultra-precise manufacturing techniques, delivering interconnect solutions that meet the stringent requirements of mission-critical applications. From life-saving medical devices to high-performance aerospace systems, High Precision Flexible Circuit Assembly ensures that electronic components integrate seamlessly, transmit signals accurately, and withstand extreme operating conditions. As industries demand increasingly miniaturized, high-density, and reliable electronic systems, the role of this assembly technology in driving innovation and ensuring operational safety has become irreplaceable.

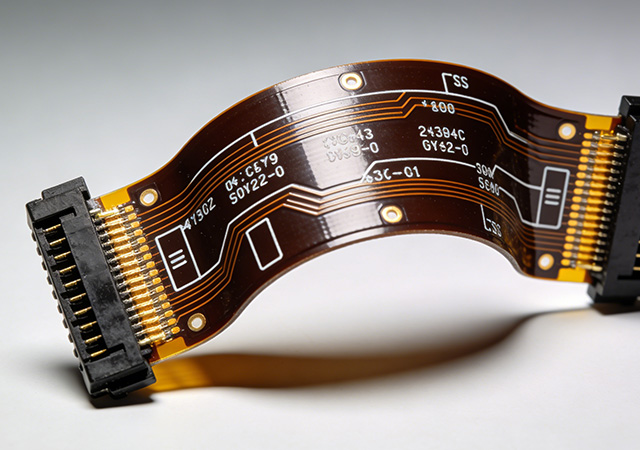

In the wave of electronic industry innovation, flexible circuit has emerged as a transformative foundational component, reshaping the design paradigm and application boundaries of electronic products. Unlike rigid printed circuit boards that restrict form and adaptability, flexible circuit features inherent flexibility, lightweight properties, and reliable electrical performance, enabling electronic devices to break free from traditional structural constraints. From daily consumer electronics to industrial automation and precision medical equipment, flexible circuit serves as the "vascular system" that connects components and transmits signals, laying a solid foundation for the development of flexible, portable, and intelligent electronic products. As global demand for high-performance and adaptive electronics continues to rise, the strategic value of flexible circuit in driving industry upgrading has become increasingly prominent.

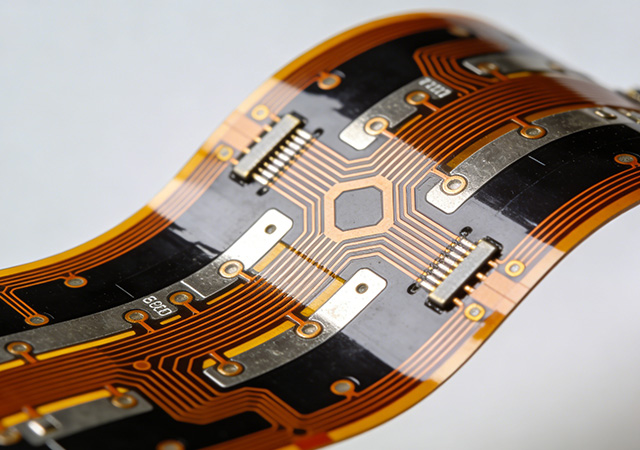

In the dynamic landscape of electronic product development, the demand for personalized, high-performance components has made customize flexible circuit a cornerstone of innovation. Unlike standard flexible circuits that offer limited adaptability, a customize flexible circuit is engineered to meet the unique spatial, functional, and environmental requirements of specific applications. From compact wearable devices to rugged industrial equipment, customize flexible circuit breaks through the design constraints of traditional electronic components, enabling engineers to translate creative concepts into practical, efficient products. As industries ranging from consumer electronics to smart manufacturing pursue greater product differentiation, the role of customize flexible circuit in delivering tailored solutions has become increasingly indispensable.

In the highly competitive global electronics market, brand differentiation and product adaptability have become key drivers of success. OEM Custom Flexible Circuit Design emerges as a strategic collaboration model, bridging the gap between electronic brands’ market demands and professional flexible circuit technology. Unlike standard flexible circuit solutions that offer one-size-fits-all options, OEM Custom Flexible Circuit Design provides tailored design services based on brands’ specific product positioning, functional requirements, and market segments. By integrating seamlessly with brands’ R&D and production systems, this design service enables the creation of unique, high-performance electronic products that stand out in the market, making it an indispensable collaborative tool for brands pursuing long-term growth and market leadership.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB