-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

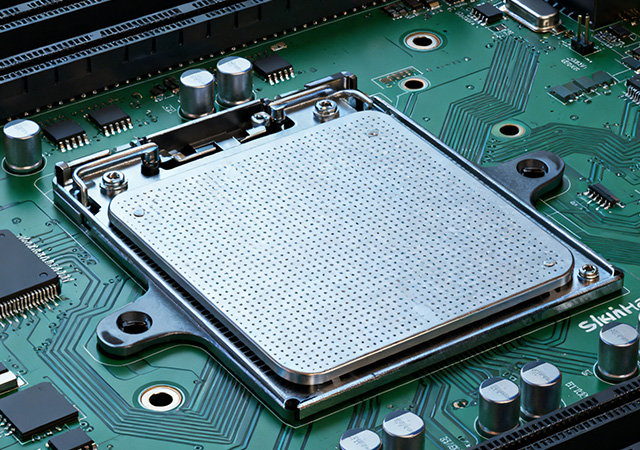

An ISO 9001 Sinkpad PCB manufacturer stands out in the high-power electronics sector by embedding customer-centricity into every layer of its quality management system (QMS). Beyond compliance with the international standard’s core tenets—process control, risk mitigation, and continuous improvement—these manufacturers tailor ISO 9001 requirements to address the unique needs of industries relying on Sinkpad PCB: electric vehicles (EVs), renewable energy, and precision industrial equipment. In a market where product failure can lead to costly downtime or safety risks, ISO 9001 certification serves as a trusted benchmark for reliability, distinguishing certified manufacturers from competitors and fostering long-term customer partnerships. This article explores how ISO 9001-driven Sinkpad PCB manufacturers deliver customer value, adapt quality practices to diverse applications, leverage digital tools for quality excellence, and guide customers in selecting the right partner.

Sinkpad PCB is a specialized high-performance PCB variant engineered for extreme thermal and electrical loads, integrating optimized sinkpad structures with advanced copper-based cores (pure copper, diamond/copper composites, or copper-aluminum hybrids). Unlike conventional PCBs that prioritize signal routing alone, sinkpad PCBs balance three core objectives: efficient heat dissipation from high-power components (e.g., IGBTs, GaN devices), reliable high-current transmission, and maintenance of signal integrity (SI) & electromagnetic compatibility (EMC). Widely adopted in electric vehicles (EVs), 5G/6G infrastructure, and industrial power electronics, sinkpad PCBs resolve the bottleneck of power density growth in compact electronic systems. This article systematically explores sinkpad PCB’s architectural design, key design rules, manufacturing standards, industry compliance, and scenario-specific optimizations, providing a comprehensive engineering guide for high-power PCB development.

Sinkpad Copper Core stands as the core functional component of high-performance PCBs, directly determining the thermal dissipation efficiency and current-carrying capacity of power electronic systems. By integrating pure copper or advanced copper-based composites into optimized sinkpad structures, it addresses the fundamental challenge of concentrated heat and high-current transmission in compact devices—from EV powertrains to 5G base stations. Unlike conventional metal cores, modern sinkpad copper cores leverage material science breakthroughs (such as diamond/copper composites) and precision engineering to resolve long-standing dilemmas of thermal expansion mismatch and interface thermal resistance. This article delves into the material evolution, structural design principles, manufacturing breakthroughs, and cutting-edge applications of sinkpad copper cores, highlighting their pivotal role in advancing high-power electronics.

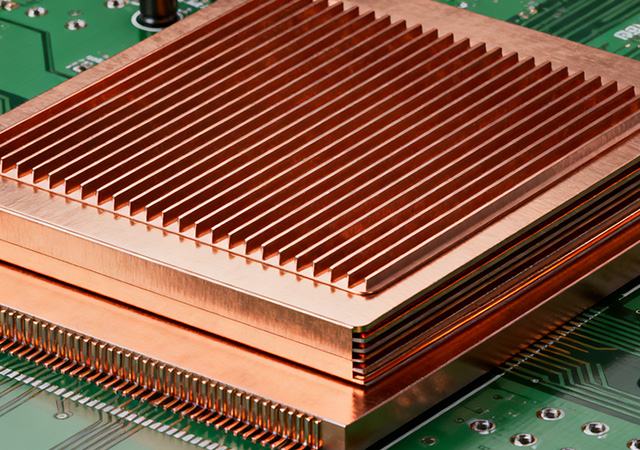

Thick Copper Sinkpad PCB Design has become an indispensable solution for high-power electronic systems demanding exceptional current-carrying capacity and thermal resilience. By integrating heavy copper layers (typically 1oz and above) with optimized sinkpad structures, this specialized design addresses the dual challenges of managing large electrical loads and dissipating concentrated heat—critical pain points in applications ranging from NEV charging modules to industrial power inverters. As electronic devices push toward higher power densities and compact form factors, Thick Copper Sinkpad PCB Design resolves the tradeoff between performance and reliability, outperforming standard copper-core PCBs in extreme operating conditions. This article explores the core design advantages, engineering principles, manufacturing precision, targeted applications, and future innovations of this advanced PCB technology.

High Thermal Sinkpad Copper Core has emerged as a game-changing solution for addressing the thermal challenges of modern high-power electronic systems. By leveraging copper’s exceptional thermal conductivity and integrating a specialized sinkpad structure, this technology delivers unmatched heat dissipation capabilities while maintaining electrical isolation and mechanical stability. As electronic devices continue to shrink in form factor while handling increasing power densities—from industrial power converters to advanced lighting systems—High Thermal Sinkpad Copper Core provides a critical pathway to prevent overheating, extend component lifespans, and ensure reliable performance. This article explores the core advantages, design principles, manufacturing breakthroughs, key applications, and future innovations of this advanced thermal management solution.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB