-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

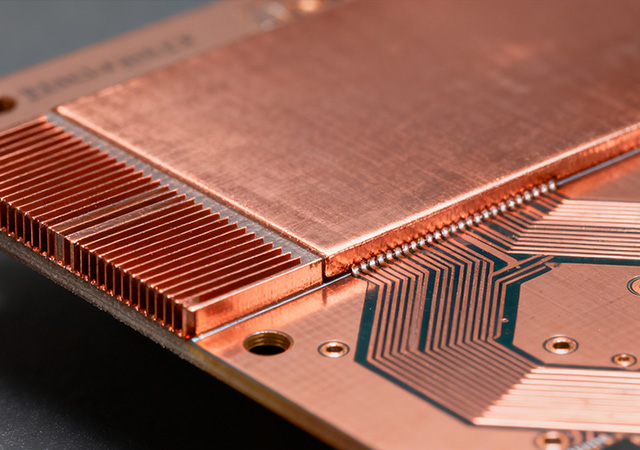

In the rapidly evolving landscape of high-power electronics, thermal management and current handling capability stand as make-or-break factors for device reliability and performance. The 2oz Copper Double Sided Sinkpad has emerged as a critical solution, addressing the dual challenges of efficient heat dissipation and stable high-current operation in compact electronic designs. Unlike conventional PCBs that often require external heat sinks or conductive enhancements, this specialized PCB integrates core functionalities into a single, streamlined structure—making it indispensable for industries pushing the boundaries of power density.

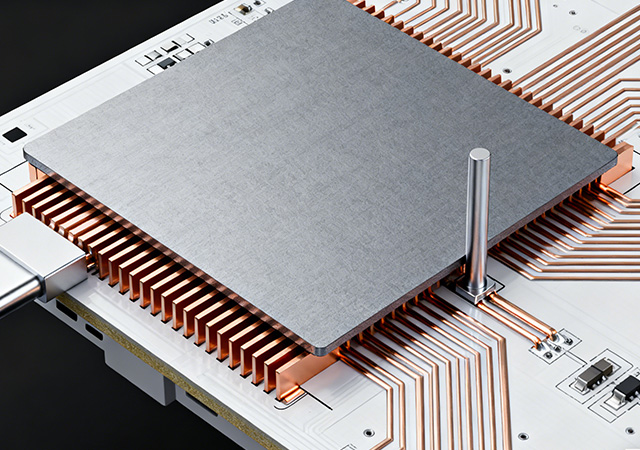

ENIG Finish Double Sided SinkPAD refers to a double-sided SinkPAD PCB that uses ENIG (Electroless Nickel Immersion Gold) as its surface finish. It combines the dual advantages of a double-sided SinkPAD’s integrated thermal management and ENIG’s stable surface performance, making it a preferred choice for high-power, high-precision electronic devices. Below is a detailed breakdown of its core features, key strengths, and typical applications:

Sinkpad PCB is a specialized thermal management solution designed for high-power electronic systems, integrating built-in thermal sink structures directly into the PCB substrate. Unlike standard PCBs that rely on external heat dissipation components, sinkpad PCB embeds a dedicated metal-based sink (typically aluminum, copper, or ceramic-metal hybrid) within the board layout—working in tandem with thermal pads to resolve concentrated heat buildup. Its core advantage lies in integrated thermal-mechanical design: eliminating the need for separate heat sinks, reducing overall device size, and ensuring efficient heat transfer from components (LEDs, semiconductors, power modules) to the external environment. Suitable for power ranges from 10W to 500W, sinkpad PCB dominates scenarios where compactness and reliability are critical, from LED lighting to new energy vehicles. This article simplifies the core logic, synergistic design, key applications, and future trends of sinkpad PCB, focusing o

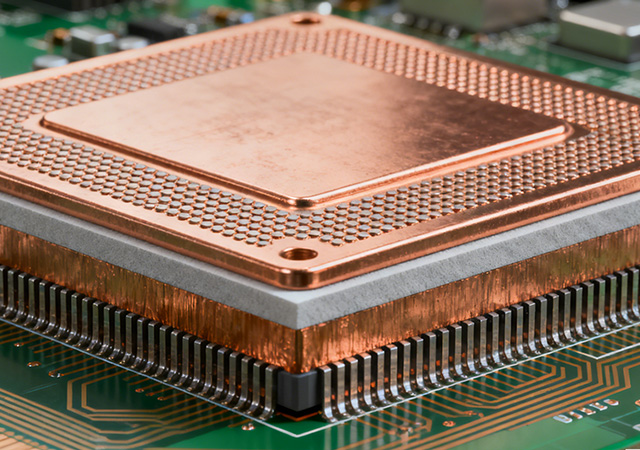

Thermal Pad MCPCB (Metal Core PCB) has established itself as a versatile thermal management platform for high-power electronic systems, integrating high-conductivity thermal pads with specialized metal cores (aluminum, copper, ceramic-metal hybrid) to resolve heat dissipation bottlenecks across power ranges (10W-500W). Unlike single-substrate solutions, Thermal Pad MCPCB adapts to diverse performance demands—from cost-sensitive mass production to extreme-power scenarios and harsh-environment applications. As electronic devices pursue higher power density, smaller footprints, and broader environmental adaptability, its core advantage lies in customizable thermal-mechanical-electrical synergy, enabling dominance across sectors from consumer electronics to aerospace. This article explores the universal technical framework, metal core-thermal pad matching strategies, cross-power design optimizations, and high-value applications, providing a streamlined guide for multi-scenario thermal mana

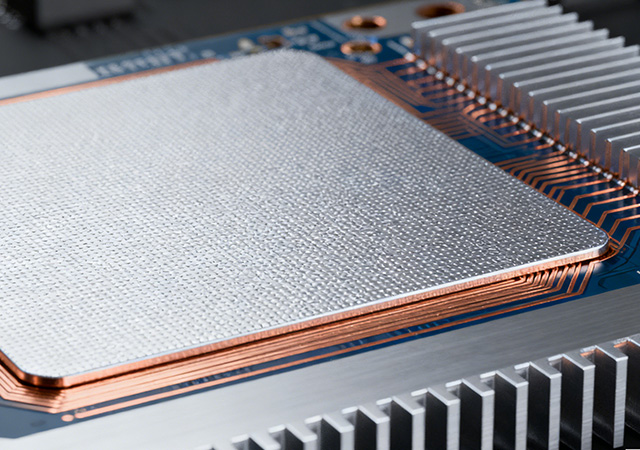

Aluminum Base Thermal Pad PCB has become a mainstream thermal management solution for mid-to-high-power electronic systems, combining the structural advantages of aluminum base PCBs (lightweight, rigid, cost-efficient) with the interface heat transfer optimization of high-conductivity thermal pads. Unlike copper base or ceramic base alternatives that prioritize extreme performance but incur higher costs, aluminum base designs strike a balance between thermal efficiency, manufacturability, and cost—making them ideal for mass-produced applications from LED lighting to consumer electronics fast chargers. As electronic devices demand smaller form factors and higher power densities while controlling production costs, Aluminum Base Thermal Pad PCB resolves the core pain point of "efficient heat dissipation at scale" by leveraging aluminum’s natural heat spreading capability and thermal pads’ gap-filling performance. This article explores the unique value proposition, material synergy, design

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB