-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

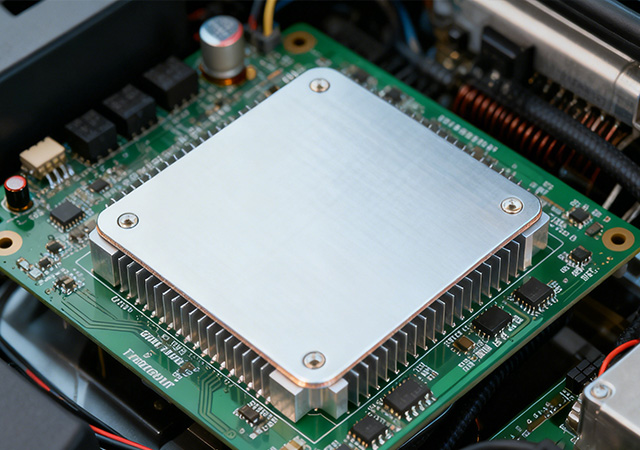

In the era of electrified, connected, and autonomous vehicles, automotive electronics are becoming increasingly complex and power-dense. Automotive Sinkpad PCB has emerged as a foundational component, designed to meet the stringent demands of vehicle environments—combining integrated thermal management, mechanical durability, and electrical stability. Unlike generic PCBs, this specialized solution is engineered for the unique challenges of automobiles, from under-hood vibration to compact cabin layouts, ensuring critical systems operate reliably throughout a vehicle’s lifespan. For automakers and tier suppliers, Automotive Sinkpad PCB is more than a circuit board; it’s a strategic enabler of safer, more efficient, and technologically advanced vehicles.

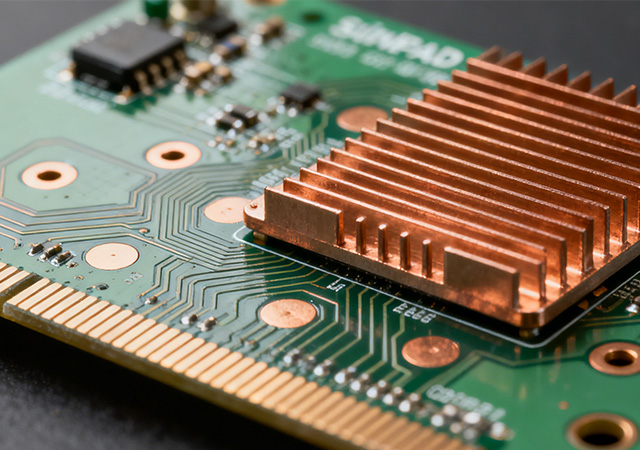

In the harsh operating conditions of modern automobiles—where under-hood temperatures can soar, and electronic systems face continuous thermal stress—High Temperature Sinkpad Auto PCB has become an indispensable component. Designed specifically to thrive in extreme heat, this specialized PCB merges the integrated thermal management of sinkpad technology with high-temperature-resistant materials and construction. It addresses the critical challenge of maintaining reliability in automotive electronics exposed to sustained high temperatures, from electric vehicle (EV) powertrains to engine control units (ECUs). For automakers and tier suppliers, this PCB delivers the thermal resilience needed to ensure safety, performance, and longevity in the most demanding vehicle systems.

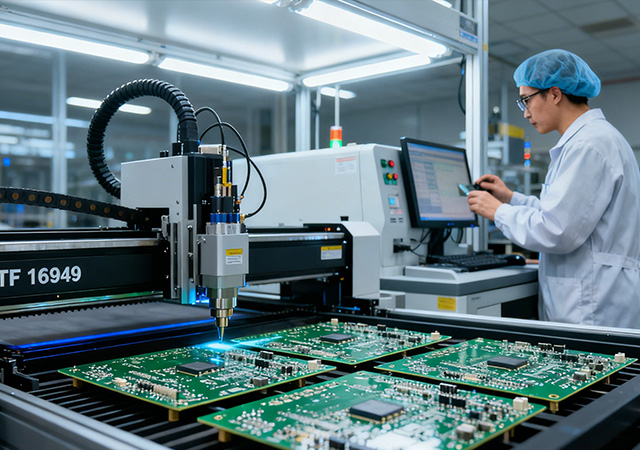

In the demanding landscape of automotive electronics, where safety, durability, and performance are non-negotiable, the IATF 16949 Sinkpad Automotive PCB has emerged as a critical component. Designed to meet the rigorous quality management requirements of the automotive industry, this specialized PCB combines the integrated thermal management of sinkpad technology with the strict compliance framework of IATF 16949. It addresses the unique challenges of vehicle electronics—extreme temperature fluctuations, vibration, and high power density—delivering a solution that ensures long-term reliability in critical systems from powertrains to advanced driver assistance systems (ADAS). For automakers and tier suppliers, this PCB is more than a component; it’s a foundational element of safe, efficient, and compliant automotive electronics.

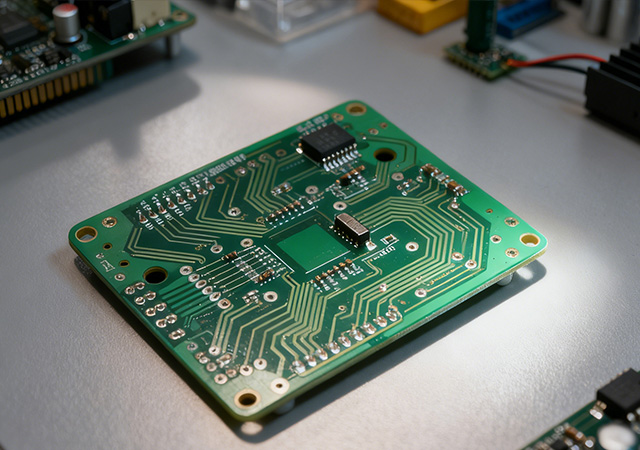

As electronic devices evolve toward higher power densities and smaller form factors, thermal management has evolved from a secondary consideration to a critical design pillar. Sinkpad PCB has emerged as a definitive solution, redefining how heat is managed in high-power systems by integrating dedicated thermal sink structures directly into the PCB architecture. Unlike conventional PCBs that rely on external cooling solutions, Sinkpad PCB merges electrical functionality with thermal efficiency, addressing the core challenge of dissipating concentrated heat without compromising design flexibility or reliability. This makes it an indispensable component for industries ranging from consumer electronics to industrial automation and beyond.

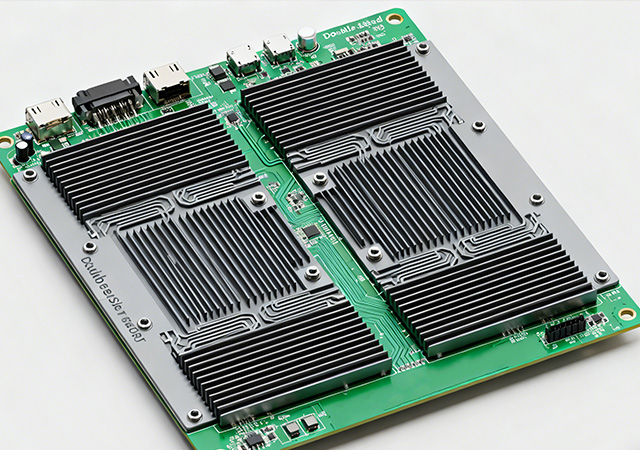

In the era of miniaturized, power-dense electronics, the ability to manage heat while optimizing circuit layout has become a defining challenge for engineers. The Double Sided SinkPAD Board emerges as a transformative solution, reimagining PCB design by integrating dedicated thermal management structures directly onto both sides of the board. Unlike traditional PCBs that treat heat dissipation as an afterthought, this specialized board unifies thermal performance, layout flexibility, and structural integrity—catering to the evolving needs of industries where space constraints and reliability are non-negotiable.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB