-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

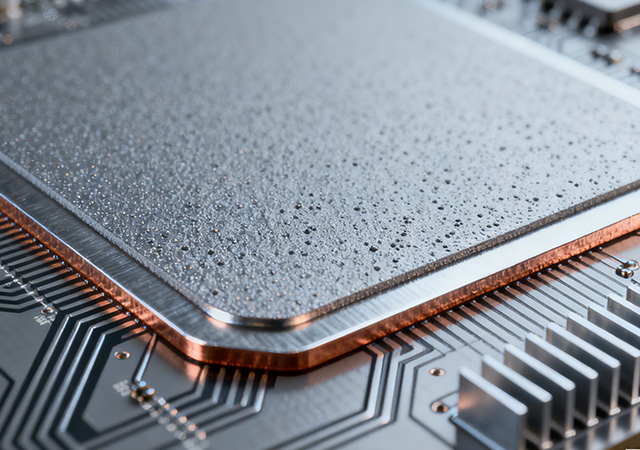

High Conductivity Thermal Pad MCPCB (Metal Core PCB) has emerged as a pivotal thermal management solution for high-power electronic systems, addressing the critical challenge of efficient heat transfer in compact, power-dense designs. Unlike standard MCPCBs that rely on basic thermal layers, this specialized variant integrates high-performance thermal pads—engineered to minimize thermal resistance—with robust metal cores (aluminum, copper, or composite substrates). As electronic devices from high-power LEDs to industrial semiconductors push toward higher power densities and smaller form factors, High Conductivity Thermal Pad MCPCB bridges the gap between heat dissipation efficiency and structural reliability. This article explores the core synergies of thermal pads and MCPCBs, material innovations, design optimizations, targeted applications, and industry trends, highlighting their role in enabling next-generation high-performance electronics.

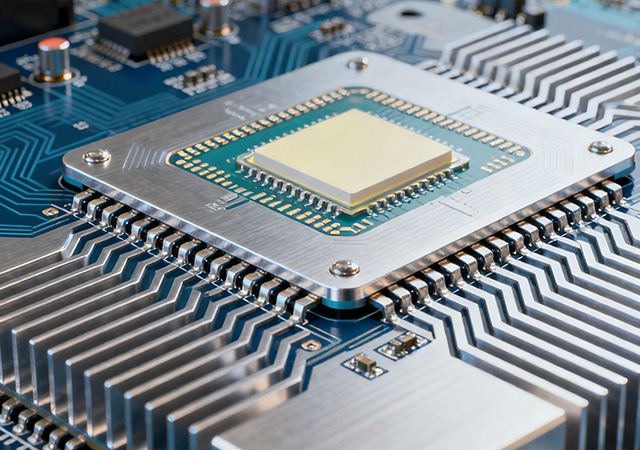

High Power LED Sinkpad PCB has become an indispensable component in modern lighting systems, addressing the critical challenge of heat dissipation that limits the performance and lifespan of high-power light-emitting diodes (LEDs). Unlike standard PCBs, which struggle to handle the concentrated thermal loads of LEDs (typically 30W and above), sinkpad designs integrate dedicated thermal layers that direct heat away from LED chips, preventing lumen depreciation and premature failure. As lighting applications evolve toward higher brightness, smaller form factors, and longer operational lifespans—from industrial floodlights to automotive headlights—High Power LED Sinkpad PCB balances thermal efficiency, mechanical stability, and electrical performance. This article explores the core design principles, performance advantages, manufacturing considerations, targeted applications, and emerging trends of this specialized PCB technology, highlighting its role in advancing high-power LED lighting

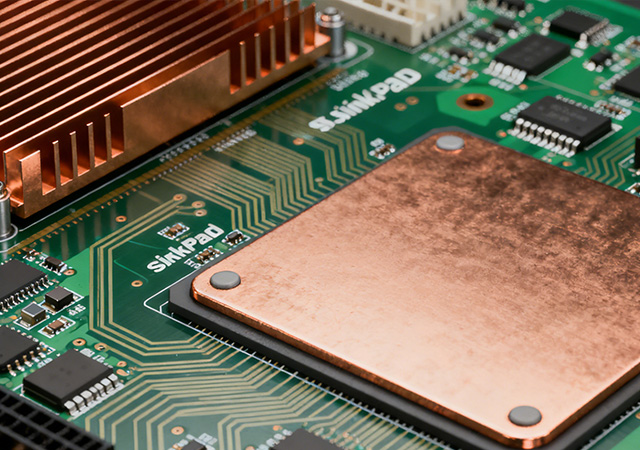

Sinkpad PCB has evolved from a niche thermal management component to a foundational technology enabling the next generation of high-power, compact electronic systems. As global demand for electrification, connectivity, and computational power accelerates, sinkpad PCBs have transcended traditional boundaries—adapting to diverse industries through material innovations, process refinements, and system-level integration. Unlike standard PCBs that prioritize signal routing alone, modern sinkpad PCBs harmonize thermal efficiency, mechanical robustness, and electrical performance, addressing the core pain points of power density growth in applications ranging from electric vehicles (EVs) to edge computing. This article explores the latest technical advancements, cross-industry integration strategies, emerging challenges, and future trajectories of sinkpad PCB technology, highlighting its role as a critical enabler of technological progress.

A qualified Sinkpad PCB manufacturer serves as the cornerstone of high-power electronic systems, as the performance stability of sinkpad structures—critical for thermal management and current-carrying capacity—directly depends on the manufacturer’s technical expertise, quality control systems, and industrialization capabilities. With the booming demand for high-power electronics in EVs, AI servers, and 5G infrastructure, sinkpad PCB manufacturers are evolving from simple processing providers to total solution partners. This article systematically analyzes the core competencies of leading manufacturers, showcases benchmark enterprise practices, reveals industry distribution characteristics, and provides actionable selection guidelines—all anchored in ISO 9001 quality standards and industry-specific certifications—to help customers identify reliable partners in a fragmented market (CR10=52.1% ).

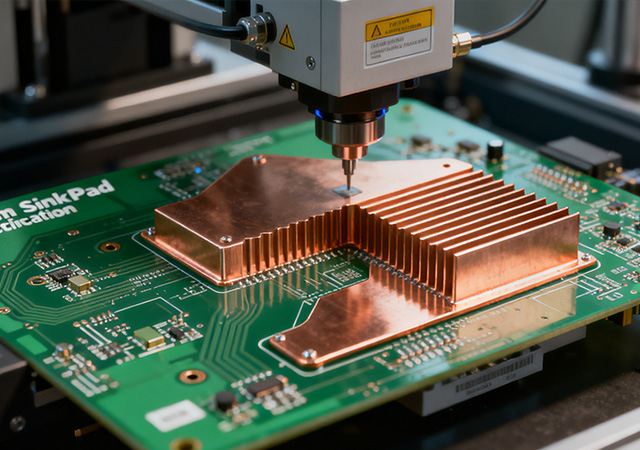

Custom Sinkpad PCB Fabrication has become a cornerstone for industries demanding tailored thermal and electrical performance, as off-the-shelf solutions often fail to address unique form factors, power densities, or environmental constraints. When paired with ISO 9001 certification, custom fabrication ensures that personalized designs—from compact wearable electronics to rugged industrial power modules—maintain uncompromised quality, reliability, and compliance. ISO 9001’s process-centric framework provides the structure to navigate the complexities of custom manufacturing, balancing flexibility with strict quality control. This article explores how ISO 9001-certified manufacturers deliver custom Sinkpad PCB solutions, covering key fabrication stages, quality integration, industry-specific adaptations, and customer collaboration workflows.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB