-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

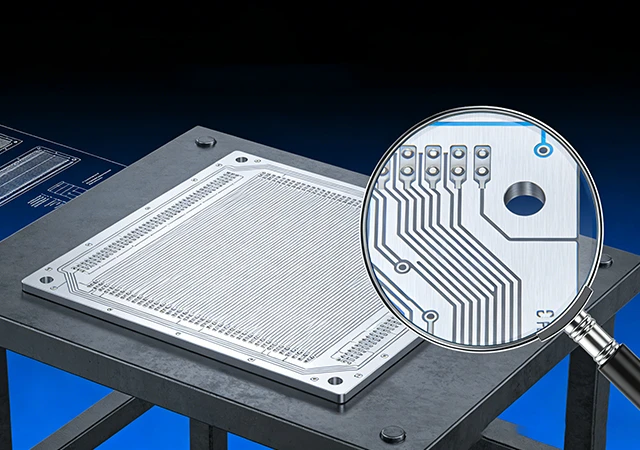

Apollo PCB is a professional aluminum PCB manufacturer providing high-quality aluminum PCB boards, including single-layer, multi-layer, and bendable designs for LED, automotive, and industrial applications.

Apollo PCB is a trusted metal core PCB manufacturer and supplier in China, providing high-quality aluminum and copper MCPCBs for LED lighting, automotive, and industrial electronics.

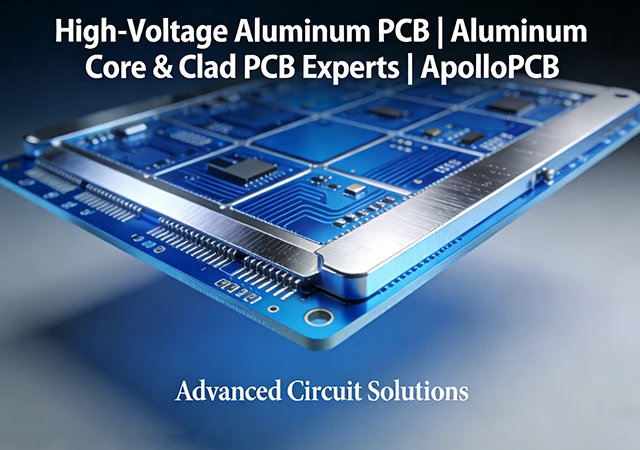

Leading aluminum pcb manufacturer in China specializing in high-voltage aluminum core pcb, 2 layer aluminum pcb, and LED light aluminum PCB solutions. Master thermal dissipation and dielectric strength today.

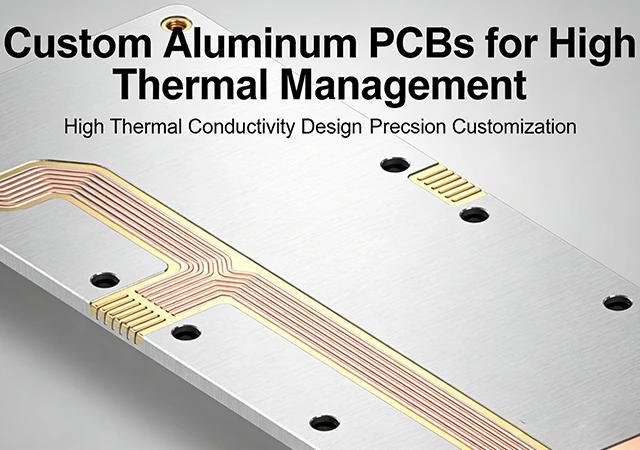

Get high-performance custom Aluminum PCB solutions. As a specialized Metal Core PCB manufacturer, ApolloPCB delivers up to 4.0 W/m·K thermal conductivity for LED, automotive, and power modules. Fast prototyping & IPC Class 3 quality. Request your technical quote today.

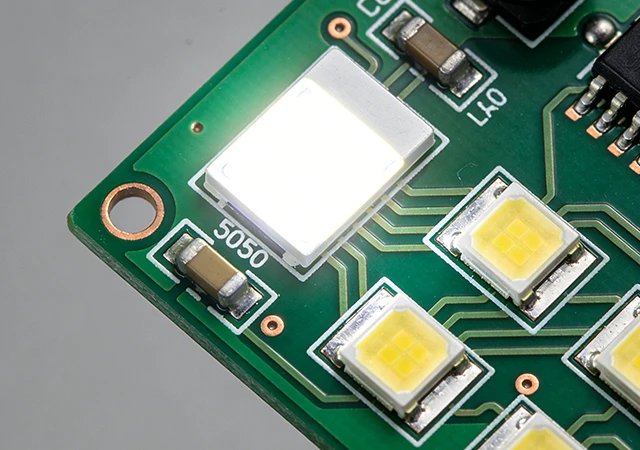

Master SMD LED package size specifications with our comprehensive chart. Compare 0402, 0603, 2835, 3528, and 5050 LED dimensions. Get expert LED PCB assembly tips and footprint guides from ApolloPCB. Download the guide.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB