-

- PCB TYPE

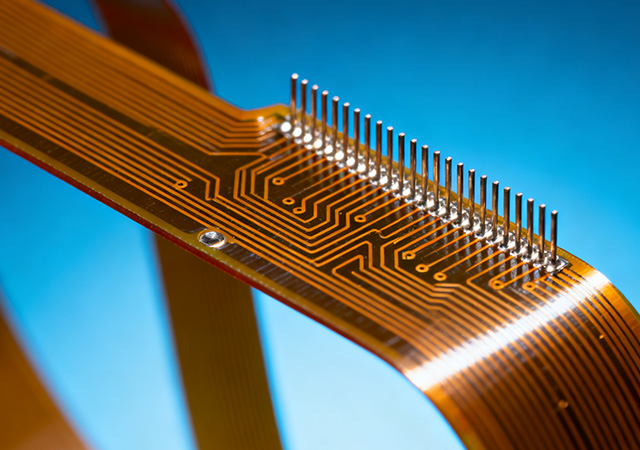

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

As electronic devices evolve toward ultra-miniaturization, high integration, and high-frequency operation, the demand for flexible printed circuits (FPCs) with superior density and signal performance has surged. A professional 4 Layer HDI FPC Manufacturer emerges as a critical enabler in this landscape, specializing in the production of 4-layer high-density interconnect (HDI) FPCs that combine the flexibility of traditional FPCs with the high-density routing capabilities of HDI technology. Unlike standard FPC manufacturers, these specialized providers possess unique expertise in optimizing 4-layer stackups, fabricating micro blind/buried vias, and ensuring signal integrity—key requirements for powering next-generation electronic products. For brands in high-end consumer electronics, medical devices, and automotive ADAS, partnering with a reputable 4 Layer HDI FPC Manufacturer is essential to translating innovative designs into high-performance, reliable products.

As the global electronics industry marches toward miniaturization, flexibility, and intelligence, the role of a professional FPC manufacturer has evolved from a mere component supplier to a core enabler of the flexible electronics ecosystem. An FPC manufacturer specializes in the research, development, and production of flexible printed circuits (FPCs)—key components that power a vast array of electronic devices by enabling seamless integration of functions in constrained spaces. Unlike generic circuit manufacturers, a dedicated FPC manufacturer possesses unique expertise in material science, precision manufacturing, and industry-specific compliance, ensuring that FPCs meet the rigorous performance and reliability requirements of diverse sectors. For electronics brands, system integrators, and innovators worldwide, partnering with a reputable FPC manufacturer is fundamental to building competitive products and advancing technological breakthroughs.

In the era of highly personalized and application-specific electronics, the role of a customize FPC manufacturer has become increasingly pivotal. Unlike one-size-fits-all FPC suppliers, a professional customize FPC manufacturer specializes in crafting flexible printed circuits (FPCs) that are precisely tailored to the unique design constraints, functional requirements, and operating environments of their clients’ products. From compact wearables to rugged industrial devices, these manufacturers bridge the gap between conceptual circuit design and practical implementation, empowering businesses across sectors to turn innovative ideas into high-performance electronic products. For companies seeking to differentiate their offerings and overcome complex engineering challenges, partnering with a skilled customize FPC manufacturer is a strategic move that enhances product value and accelerates market success.

In the fast-paced electronics industry, the demand for flexible, high-performance printed circuits (FPCs) that align with unique product designs and production scales is ever-growing. An OEM FPC Customization Services Provider emerges as a vital strategic partner, offering end-to-end tailored solutions that bridge the gap between conceptual circuit design and large-scale, consistent production. Unlike standard FPC suppliers, these providers specialize in understanding OEMs’ specific requirements—from technical specifications to branding integration and supply chain scalability—delivering customized FPCs that power a wide range of electronic devices. For OEMs across consumer electronics, automotive, medical, and industrial sectors, partnering with a reputable OEM FPC Customization Services Provider is key to enhancing product competitiveness, streamlining production, and accelerating time-to-market.

The wearable technology sector is defined by its relentless pursuit of miniaturization, comfort, and uncompromised performance—attributes that place immense demands on the underlying electronic components. A specialized Customized FPC Manufacturer for Wearables emerges as a critical partner in this ecosystem, delivering flexible printed circuits (FPCs) tailored to the unique constraints of wearable devices. Unlike generic FPC suppliers, these manufacturers combine deep expertise in wearable design requirements with agile customization capabilities, creating circuits that conform to ergonomic shapes, withstand repeated bending, and integrate seamlessly with sensors, batteries, and other compact components. For wearable brands and innovators, partnering with a dedicated customized FPC manufacturer is not just a supply chain decision; it’s a strategic enabler of products that resonate with consumers and stand out in a competitive market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB